Product Development

Technology R & D

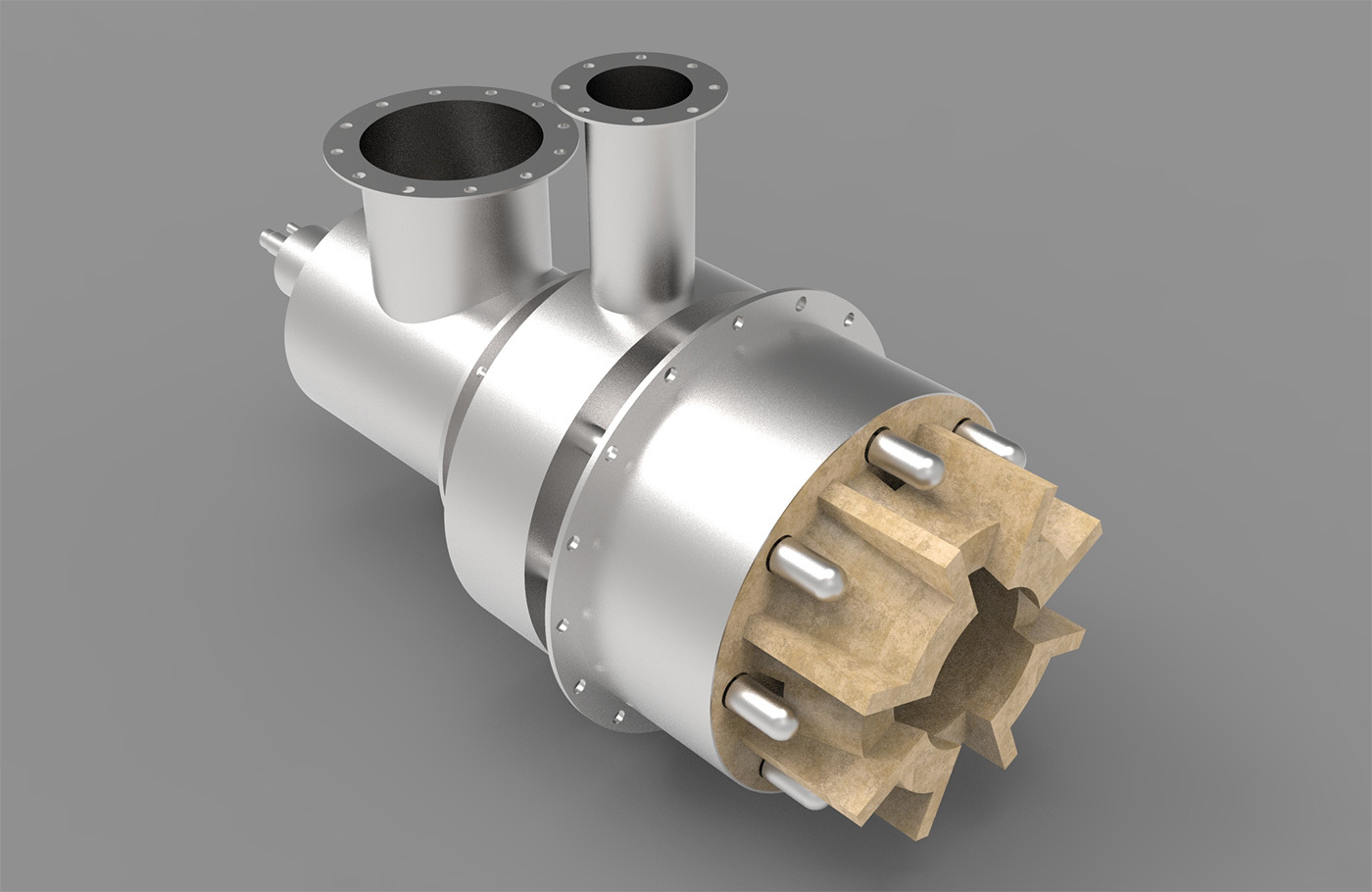

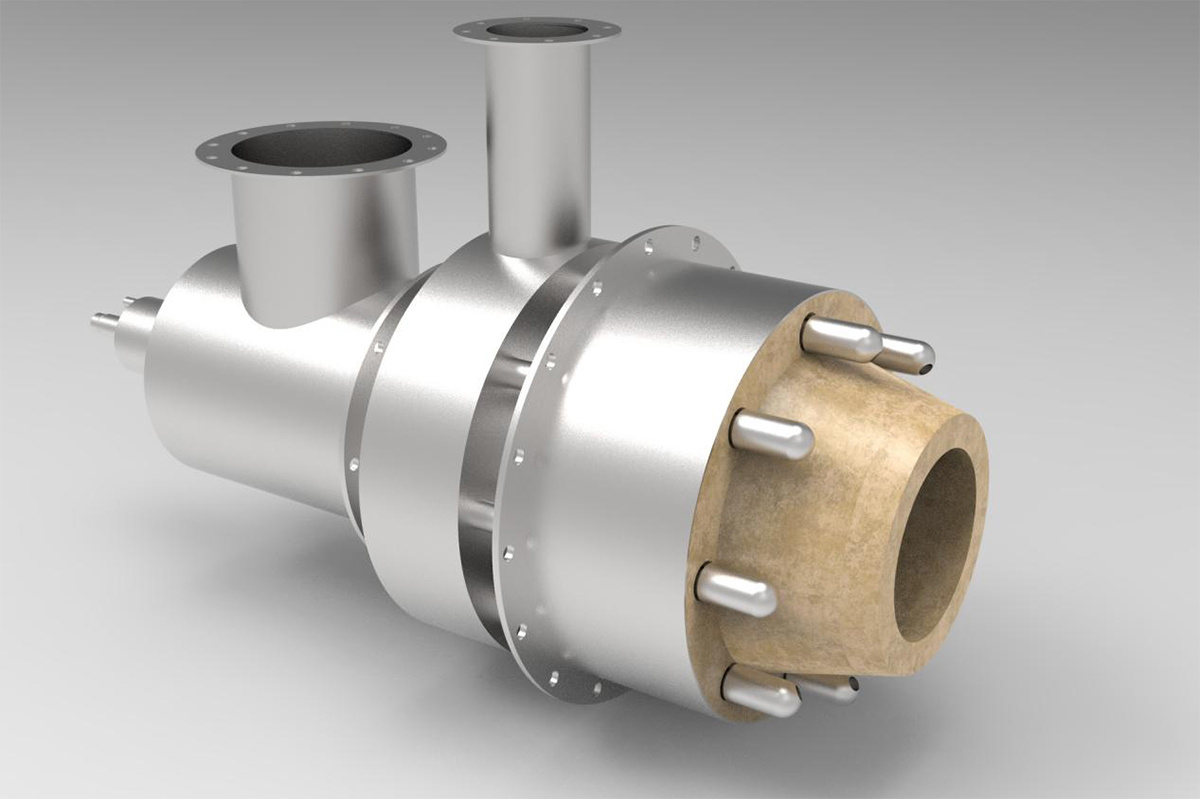

Advanced Combustion and Its Control Technology

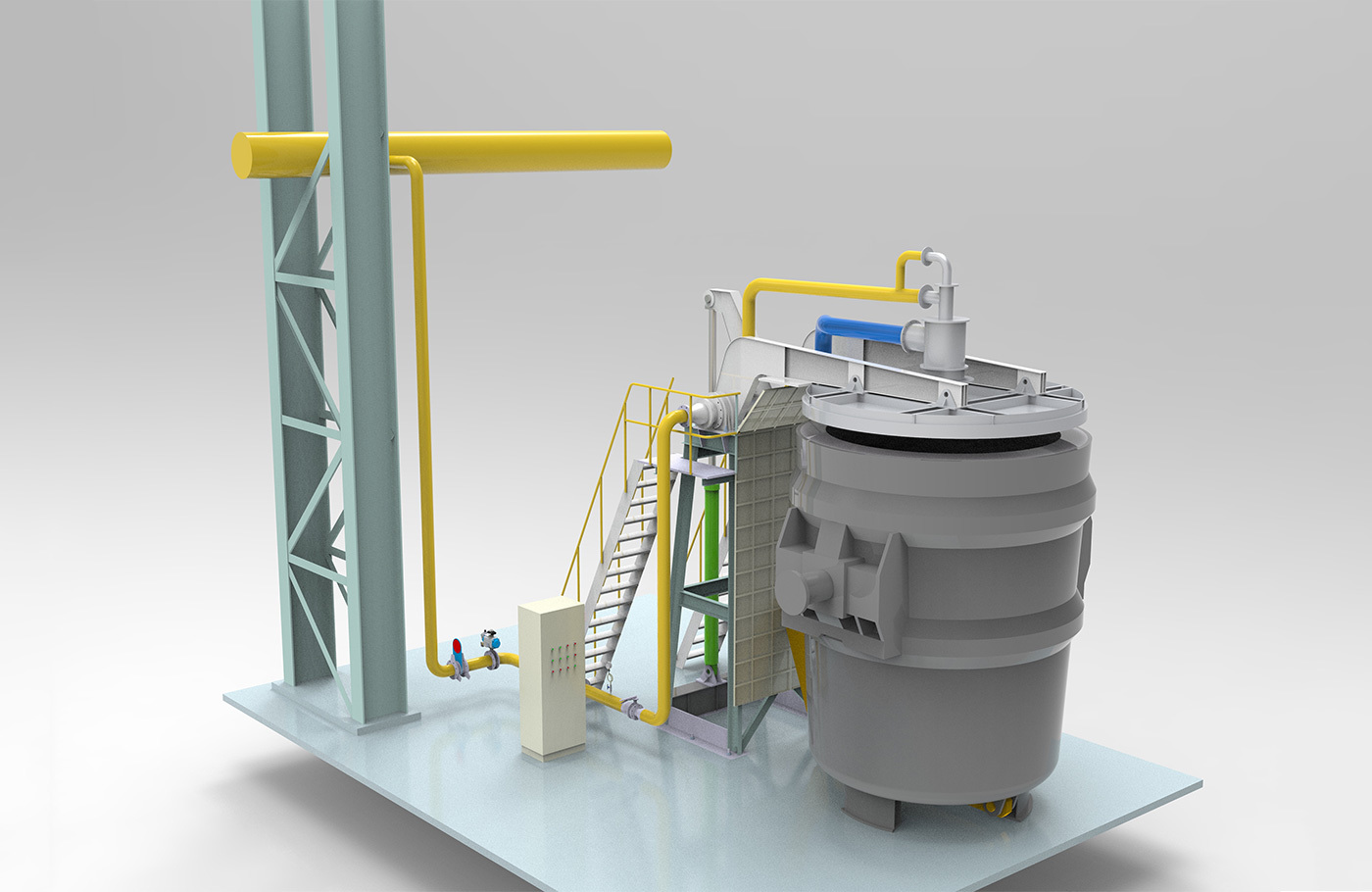

Industrial waste heat extreme recovery and utilization system and its key technologies

Key Technology of Energy Saving and Environmental Protection Comprehensive Solution for Metallurgical Walking Beam Heating Furnace

Achievement Honor

Patent

Technical (product) certification

Engineering case

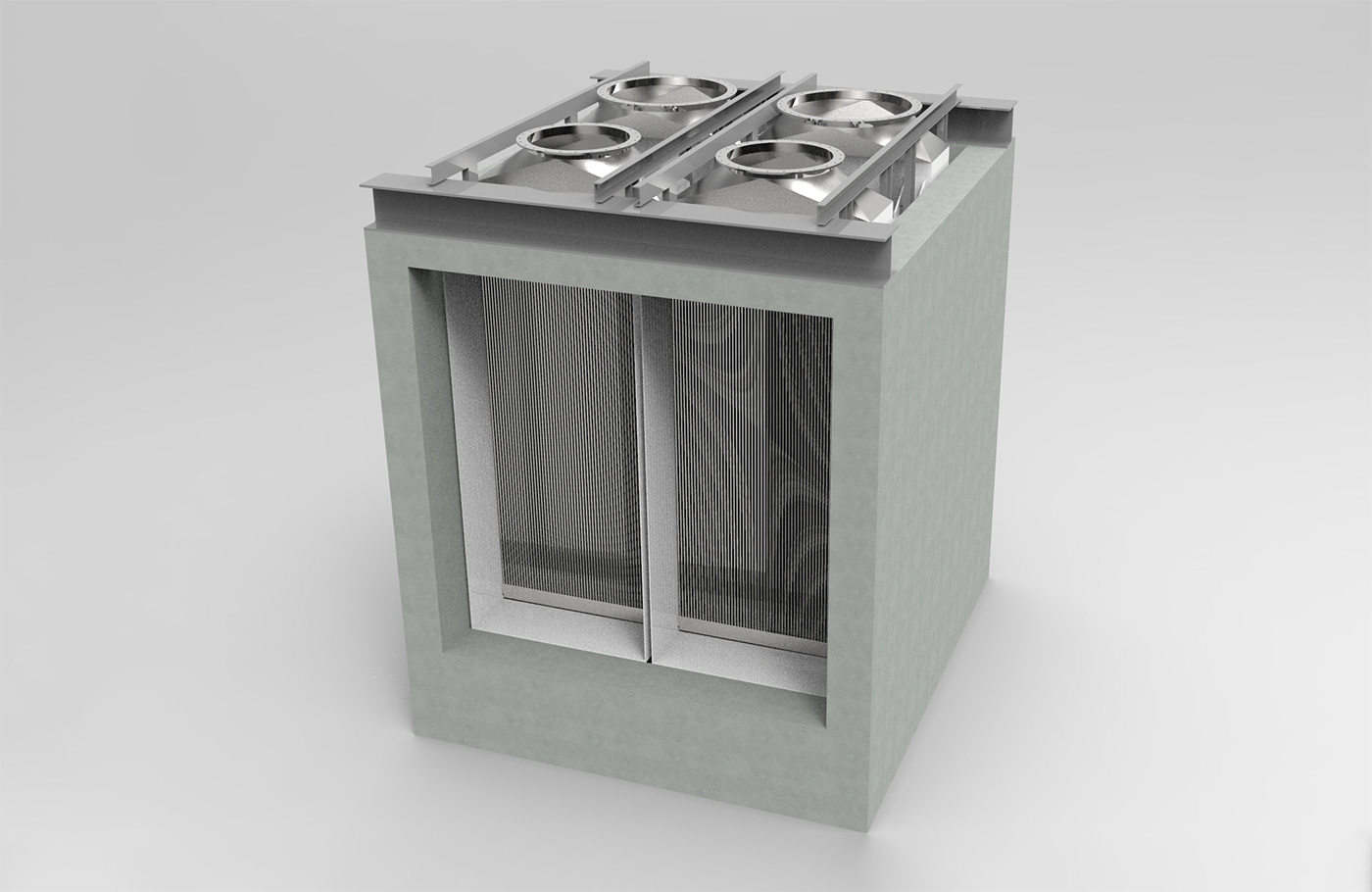

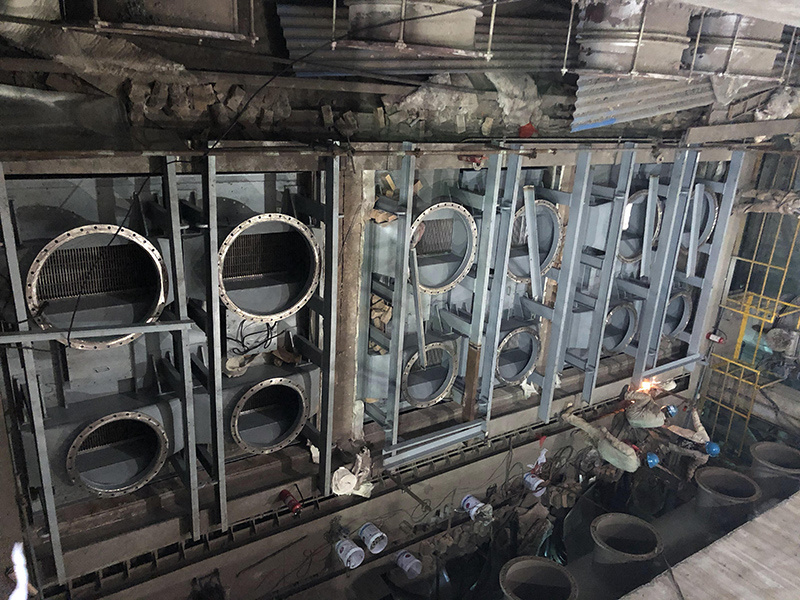

No. 1 Furnace Air Preheater Renovation Project of Meigang 1422 Line

Shanghai Meishan Iron and Steel Co., Ltd. Hot Rolling Plant 1422mm Hot Rolling Furnace No.1 was put into operation in November 1993, and completed the technical transformation of combustion and cooling system in 2009. The fuel of the furnace is high-coke mixed gas, and regular burners are used for heating and continuous combustion control. The heating furnace is a walking beam heating furnace, and the furnace type is a three-stage heating side-to-side walking beam heating furnace. The heating furnace is divided into preheating section, heating section, heating section and soaking section along the furnace length from the charging end to the discharging end. In order to fully and effectively recover the waste heat of flue gas, a tubular air preheater is set in the flue.

Meigang Hot Rolling Furnace "Reduce Oxidation Burning Loss Software Package" Project

Meishan Iron and Steel Co., Ltd. and Professor Xing Yuming of Beijing University of Aeronautics and Astronautics jointly cooperated in the technical transformation project of "Reducing Oxidation Burning Loss Software Package". The project was established in March 2017 and officially entered the project commissioning period in July, which lasted 9 months. In the course of the project, it has gone through several stages, such as manual debugging, installation of testing equipment, establishment of software package architecture, debugging and improvement of software package, and project evaluation. The results of the project are as follows:

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us