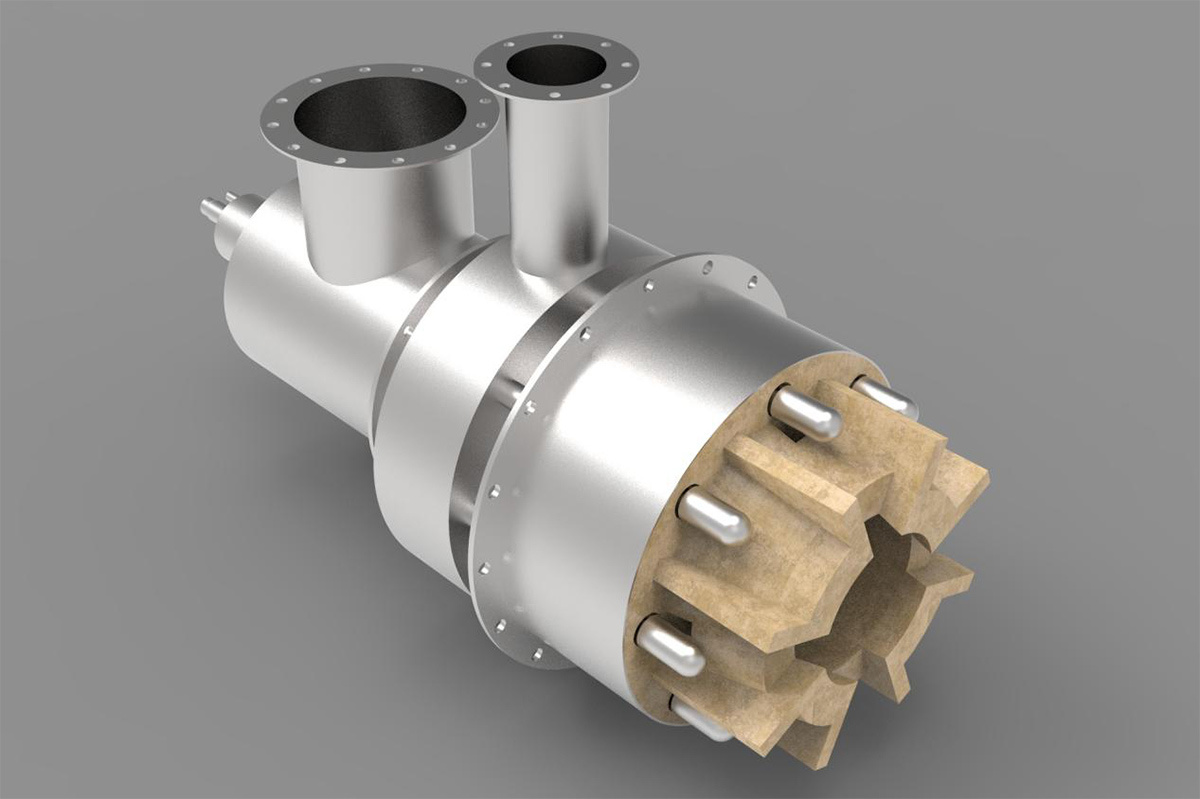

F22-Ⅲ-B type high speed low nitrogen burner

Overview

In the production process of metallurgical industry, hot rolling heating furnace is a big energy consumer. At present, there is still a lot of room for improvement in the fine control of walking beam heating furnace. Improving the control accuracy of heating furnace and reducing energy waste and product loss are of great significance to reducing carbon and nitrogen in the whole metallurgical industry. regular walking beam heating furnace refers to the slab with basically the same shape, which moves continuously inside the heating furnace, from the inlet of the heating furnace to the outlet driven by the roller, the burner arranged at the bottom and top of the heating furnace burns the billet of the flame heating furnace to reach the specific process temperature.

At present, the walking beam heating furnace in the domestic metallurgical industry mainly uses regular burners, which have simple structure and low organizational combustion technology. They mainly rely on radiation to exchange heat and have low energy utilization rate. Most of the heat is discharged with flue gas, and the thermal efficiency in the furnace is basically about 50%. In addition, the combustion temperature of different burner products may be higher due to the combustion temperature of more than 1800 ℃ during billet heating, this causes the surface of the billet during heating to react with the oxygen that does not participate in the combustion reaction of the heating furnace to generate iron oxide products, resulting in the loss of billet products. To control the degree of oxidation burning loss, the precise organization of the burner combustion technology is the key.

F22-Ⅲ-B type high speed low nitrogen burner

Adopting the nitrogen reduction strategy of staged combustion, the combustion mixed gas is divided into three stages of combustion along the axial direction. From inside to outside, they are the primary combustion zone formed by the central fuel gun ejecting gas, the secondary combustion zone formed by the first fuel gun ejecting gas, and the tertiary combustion zone formed by the second fuel gun ejecting gas, forming the flame with the center diverging to the outer layer, the mixing of gas and air in each stage of mixed gas deviates from the chemical equivalence ratio, so that each part of the flame is in a lean or rich state, reducing the combustion temperature, so as to achieve the purpose of reducing thermal nitrogen oxides.

The first nozzle and the second nozzle can be divided in the radial direction by dividing bricks, and the first nozzle and the second nozzle can be divided in the circumferential direction by dividing plates. In this way, the high-speed flue gas sprayed from the contraction channel is mixed with the gas sprayed from several second nozzles to form a columnar flame, and then mixed with the gas sprayed from several first nozzles to form a secondary flame and wrap the columnar flame, finally, a secondary combustion with excessive gas is formed. At the same time, the dividing plate divides the flame in the circumferential direction, and the divided flames are folded over each other. The folded flame surface can make the flue gas flow back, thus deeply reducing the generation of nitrogen oxides.

Related Products

High temperature plate air preheater

At present, in the hot rolling heating furnace process waste heat recovery system in the metallurgical industry, the air preheating equipment generally adopts the traditional tube type gas-gas heat exchanger, which is characterized by simple structure and low manufacturing cost, but its heat exchange efficiency and service life Performance indicators such as life are low.

View moreF22-Ⅲ-B type high speed low nitrogen burner

In the production process of metallurgical industry, hot rolling heating furnace is a big energy consumer. At present, there is still a lot of room for improvement in the fine control of walking beam heating furnace. Improving the control accuracy of heating furnace and reducing energy waste and product loss are of great significance to reducing carbon and nitrogen in the whole metallurgical industry. regular walking beam heating furnace refers to the slab with basically the same shape, which moves continuously inside the heating furnace, from the inlet of the heating furnace to the outlet driven by the roller, the burner arranged at the bottom and top of the heating furnace burns the billet of the flame heating furnace to reach the specific process temperature.

View moreContact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us