Meigang Hot Rolling Furnace "Reduce Oxidation Burning Loss Software Package" Project

Release time:

2022-02-21

Meishan Iron and Steel Co., Ltd. and Professor Xing Yuming of Beijing University of Aeronautics and Astronautics jointly cooperated in the technical transformation project of "Reducing Oxidation Burning Loss Software Package". The project was established in March 2017 and officially entered the project commissioning period in July, which lasted 9 months. In the course of the project, it has gone through several stages, such as manual debugging, installation of testing equipment, establishment of software package architecture, debugging and improvement of software package, and project evaluation. The results of the project are as follows:

Meishan Iron and Steel Co., Ltd. and Professor Xing Yuming of Beijing University of Aeronautics and Astronautics jointly cooperated in the technical transformation project of "Reducing Oxidation Burning Loss Software Package". The project was established in March 2017 and officially entered the project commissioning period in July, which lasted 9 months. In the course of the project, it has gone through several stages, such as manual debugging, installation of testing equipment, establishment of software package architecture, debugging and improvement of software package, and project evaluation. The results of the project are as follows:

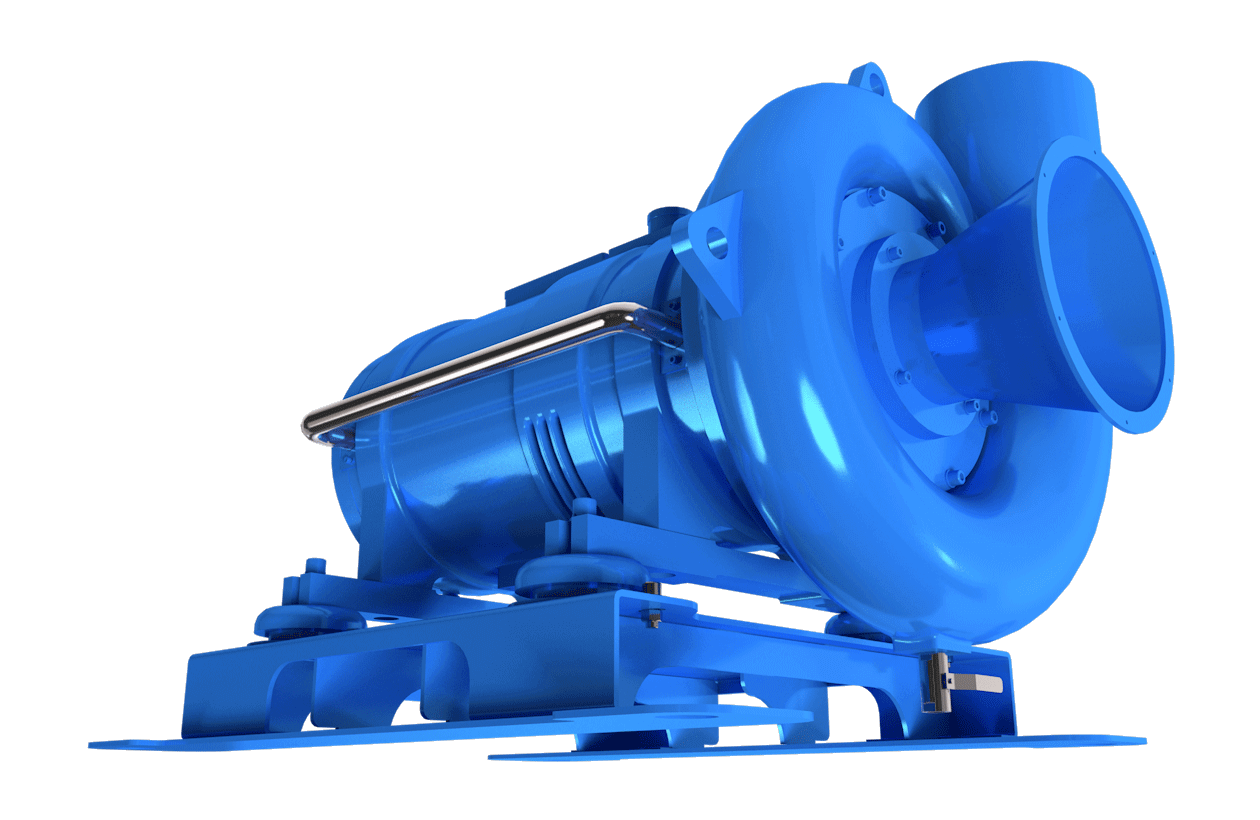

Fig.1 Hot-rolled heating furnace of Meigang

After eight months of work in the first three stages, the project has realized the continuous commissioning of the "software package". In order to verify its effect, the investment management department, hot rolling mill, Beihang and other relevant personnel have conducted special discussions on the evaluation of the project, and established the evaluation methods of the "software package" commissioning rate and failure rate, sample block experimental method and data comparison, and yield reference comparison. The main results are analyzed as follows:

According to the discussion of the evaluation scheme, several sample block experiments were carried out for different heating furnaces and working conditions during the evaluation time, and a total of 11 experiments were carried out, of which 8 were "software package" operation conditions and 3 were "software package" non-operation conditions (in the 11 experiments, due to the failure of the rolling line encountered in the first experiment, the time in the furnace was too long, and no invalid data was determined). Specific data are shown in the following table:

| Serial Number |

Date |

Furnace No. |

Time in the furnace |

Blow temperature |

Model commissioning |

burning loss rate |

Data Validity |

| 1 |

2018/3/22 |

2# |

290 |

1250 |

put into use |

0.937% |

Invalid |

| 2 |

2018/3/23 |

2# |

172 |

1183 |

put into use |

0.544% |

effective |

| 3 |

2018/3/26 |

2# |

208 |

1184 |

put into use |

0.521% |

effective |

| 4 |

2018/3/28 |

2# |

185 |

1187 |

put into use |

0.443% |

effective |

| 5 |

2018/4/3 |

1# |

233 |

1182 |

put into use |

0.468% |

effective |

| 6 |

2018/4/18 |

1# |

180 |

1202 |

put into use |

0.467% |

effective |

| 7 |

2018/4/20 |

1# |

179 |

1221 |

put into use |

0.486% |

effective |

| 8 |

2018/4/20 |

1# |

179 |

1221 |

put into use |

0.496% |

effective |

| 9 |

2018/4/24 |

1# |

189 |

1184 |

Unused |

0.700% |

effective |

| 10 |

2018/4/26 |

1# |

225 |

1217 |

Unused |

0.724% |

effective |

| 11 |

2018/5/3 |

1# |

200 |

1219 |

Unused |

0.713% |

effective |

From the data in the above table, it can be seen that except for the first time, the oxidation burning loss rate is too high due to too long time in the furnace and too high temperature, the other several times are relatively ideal. Under the operation state, the average burning loss rate is 0.489, while the non-operation state burning loss rate is 0.712, reducing the burning loss rate by 0.223. It exceeded the target of "reducing the oxidation loss rate by 0.2" signed in the technical agreement of the project.

From the comprehensive project data, the following conclusions are drawn:

1. The program of "software package" has covered all products of 1422 production line, can be put into use continuously, and has no adverse effect on production;

2. The commissioning rate and failure rate of the "software package" exceed the design level, and the applicable performance is very good, meeting the needs of heating furnace control;

3. Through the sample block experiment, the "software package" has obvious effect on reducing burning loss and can reach the predetermined target of reducing burning loss by 0.2;

4. Through the comparison of the yield, it is proved that the application of the "software package" has a great promotion effect on the yield of the rolling line, and the daily yield of the 1# furnace also exceeds the target of 0.2;

5. Through the comparison of gas consumption and exhaust gas temperature, it is proved that the "software package" has no negative effect on the fuel consumption of the heating furnace;

6, through the recent use of comparison, rolling line reflected in the edge line and other quality defects failed to prove that the "software package" has a strong correlation, that it has no significant negative impact on product quality.

Based on the above analysis, compared with the technical agreement signed before the project, the hot rolling mill's technical transformation project team determined that the "software package" project had achieved the expected effect and completed the scheduled work, which could be concluded.

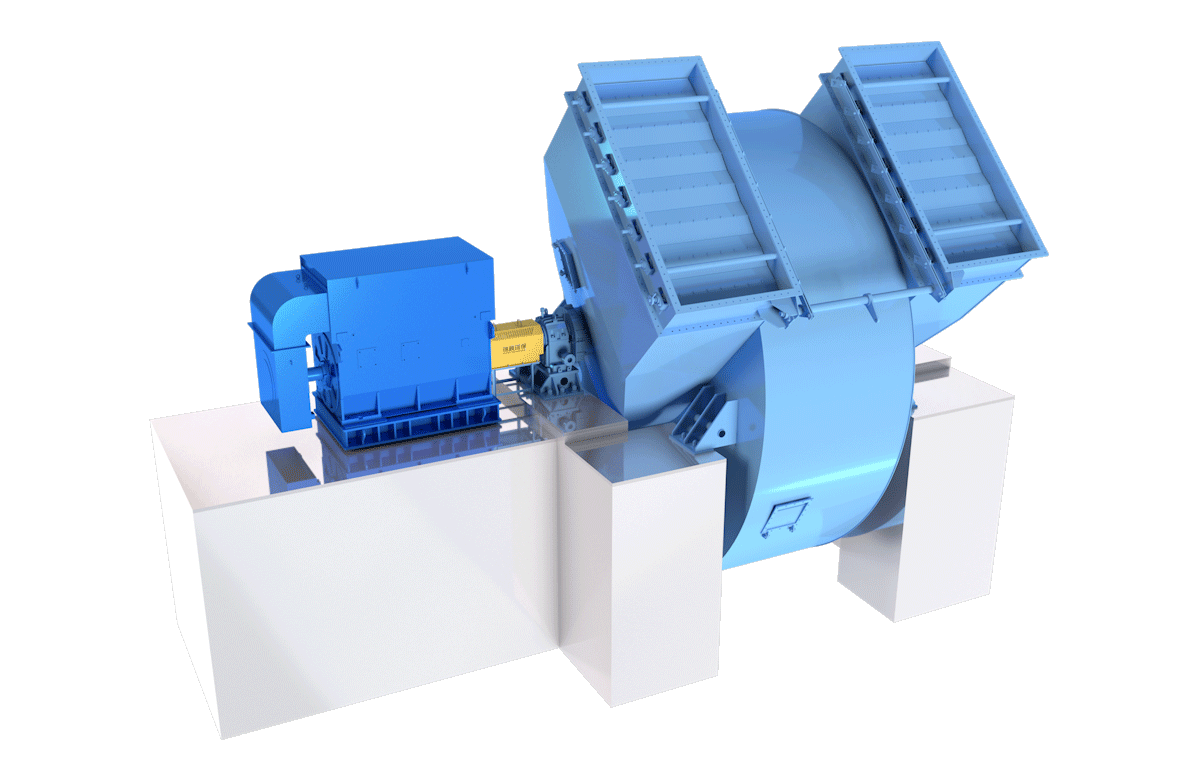

Fig.2 Formation of scale under regular working conditions

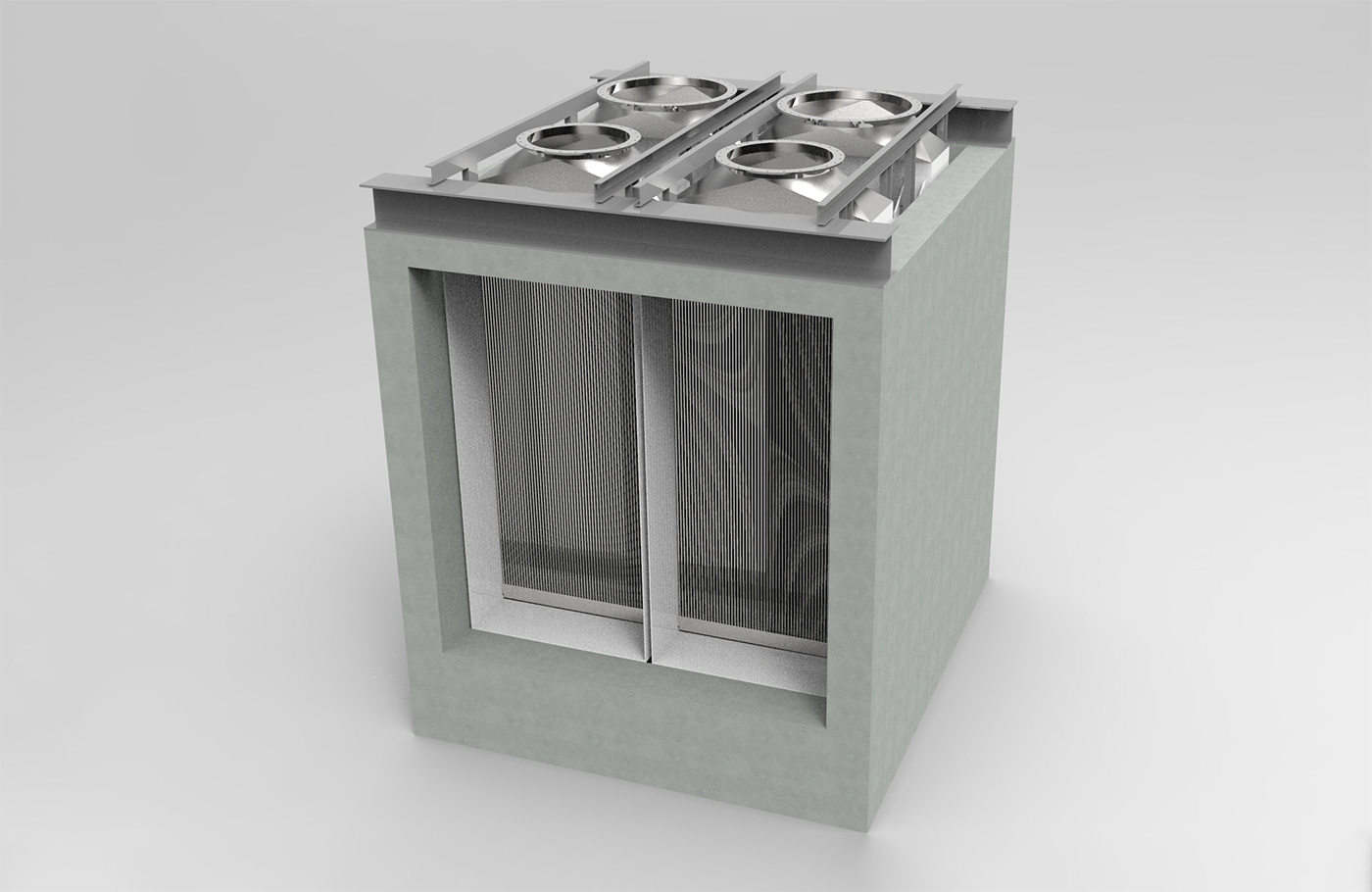

Fig.3 Formation of iron oxide scale under double atmosphere adjustment condition

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us