High temperature plate air preheater

Overview

At present, in the hot rolling heating furnace process waste heat recovery system of the metallurgical industry, the traditional tubular gas air heat exchanger is generally used for air preheating equipment. Its characteristics are simple structure and low manufacturing cost, but its heat transfer efficiency, service life and other performance indicators are relatively low.

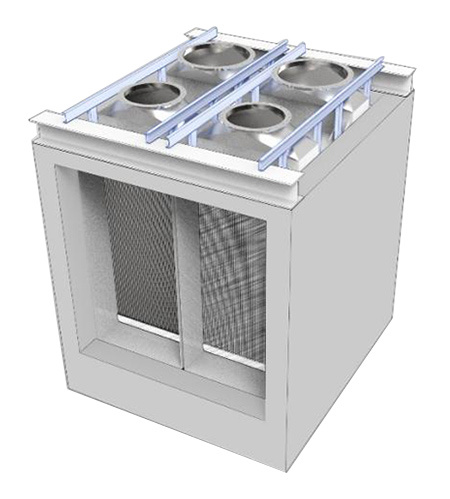

The preheating and recovery system of the metallurgical hot rolling process heating furnace generally includes an air preheater and a gas preheater, which recover the waste heat of high-temperature flue gas. By preheating the gas fuel and combustion air to be burned, most of the flue gas preheating is recovered into the heating furnace, as shown in Figure 1.

Fig. 1 Schematic diagram of preheating and recovery device of heating furnace system

Metallurgical hot rolling heating furnace air preheater technical requirements, the flue gas inlet temperature is higher, generally more than 700 ℃, even more than 850 ℃. In addition, the general flue gas is naturally ventilated through the chimney without induced draft fan, which requires strict pressure drop on the flue gas side. Ash deposition is avoided during the operation of the flue gas side. The tubular heat exchanger is due to serious ash deposition, resulting in obvious attenuation of heat exchange efficiency. Preferably, since the air preheater of the hot rolling furnace is placed in the flue and occupies an extremely limited space, a heat exchanger form with high heat exchange efficiency is required.

High temperature and high efficiency plate type air preconditioner

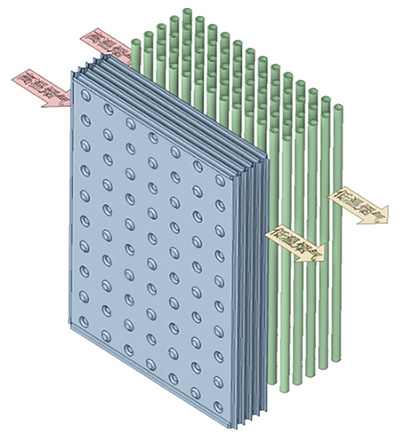

All-metal welded plate heat exchangers are used to recover flue gas heat to preheat air, and have been widely used in petrochemical, power systems and other industrial production processes. Because of its large specific surface area and high heat transfer coefficient, plate heat exchanger is an efficient heat exchanger technology. Its principle is shown in Figure 2.

Fig.2 Principle of plate heat exchanger and comparison of tube and tube

However, due to its special process application scenarios and harsh technical requirements of air preheater, the current mature plate air preheater technology cannot be directly applied to the metallurgical industry, mainly because of the higher requirements of the technical indicators mentioned above.

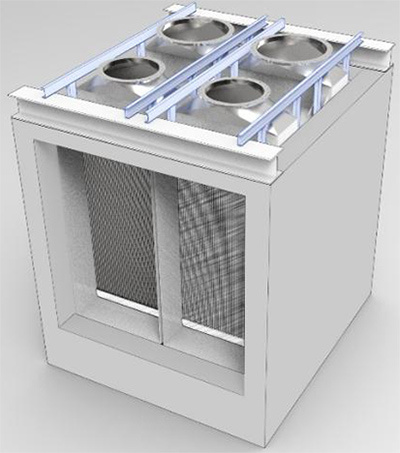

Based on this, Shanghai Rychen Company and Beijing University of Aeronautics and Astronautics jointly developed a high-temperature and high-efficiency plate air preheater technology that can be applied to metallurgical hot-rolling heating furnaces, as shown in Figure 3.

Fig.3 High temperature and high efficiency plate air preheater for metallurgical hot rolling furnace

Key technology

(1) High-efficiency and low-resistance Ding-cell enhanced heat exchange plate technology

(2) High temperature thermal protection and thermal stress solution technology

(3) Anti-fouling design technology

(4) Multi-condition design technology

(5) Large-scale heat exchange plate high temperature welding and its manufacturing technology

Technical indicators

(1) The flue gas inlet temperature is greater than 850 ℃

(2) The air outlet temperature is higher than 600 ℃

(3) The heat exchange efficiency is greater than 80%

(4) The heat exchange performance does not decay within 5 years, and the longest service life can reach 8 years

Related Products

High temperature plate air preheater

At present, in the hot rolling heating furnace process waste heat recovery system in the metallurgical industry, the air preheating equipment generally adopts the traditional tube type gas-gas heat exchanger, which is characterized by simple structure and low manufacturing cost, but its heat exchange efficiency and service life Performance indicators such as life are low.

View moreF22-Ⅲ-B type high speed low nitrogen burner

In the production process of metallurgical industry, hot rolling heating furnace is a big energy consumer. At present, there is still a lot of room for improvement in the fine control of walking beam heating furnace. Improving the control accuracy of heating furnace and reducing energy waste and product loss are of great significance to reducing carbon and nitrogen in the whole metallurgical industry. regular walking beam heating furnace refers to the slab with basically the same shape, which moves continuously inside the heating furnace, from the inlet of the heating furnace to the outlet driven by the roller, the burner arranged at the bottom and top of the heating furnace burns the billet of the flame heating furnace to reach the specific process temperature.

View moreContact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us