Anyang Iron and Steel Co., Ltd. Rolling Circulating Water System Energy Saving Project

Release time:

2022-04-07

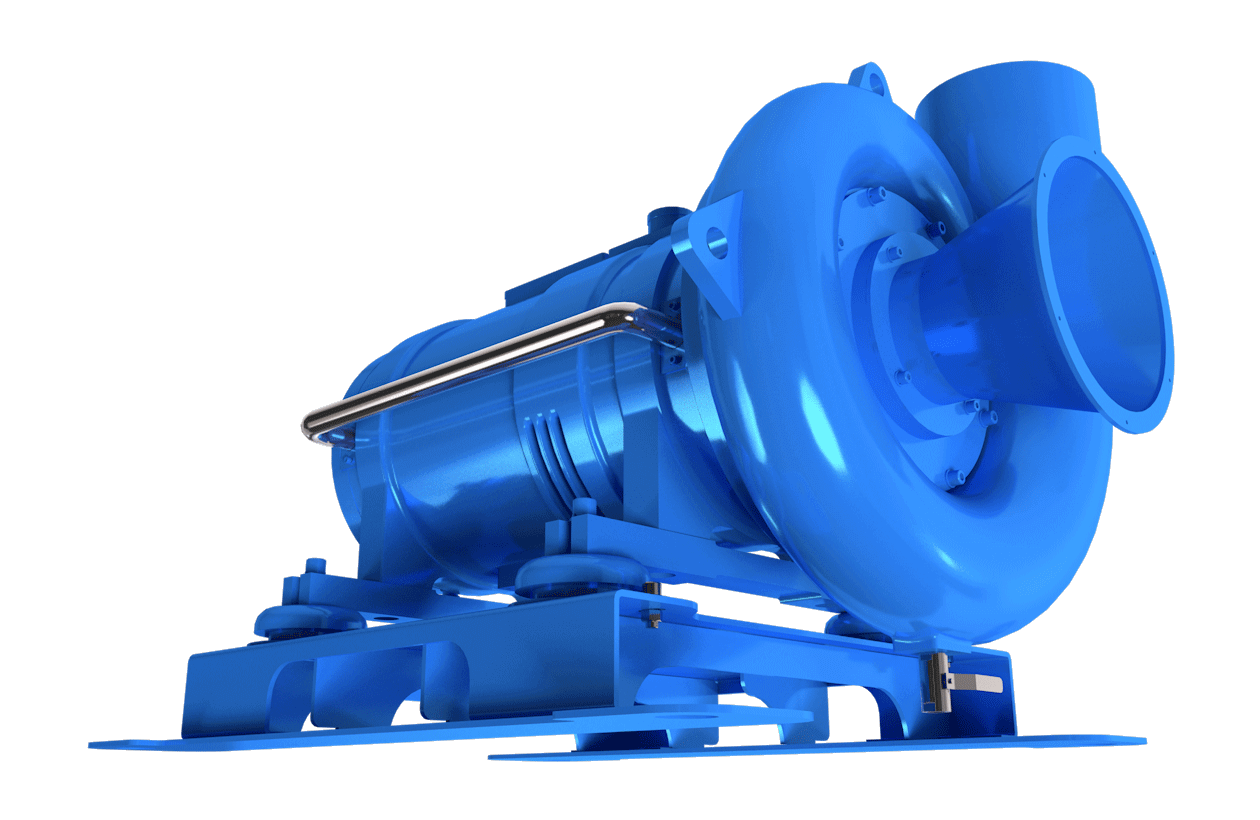

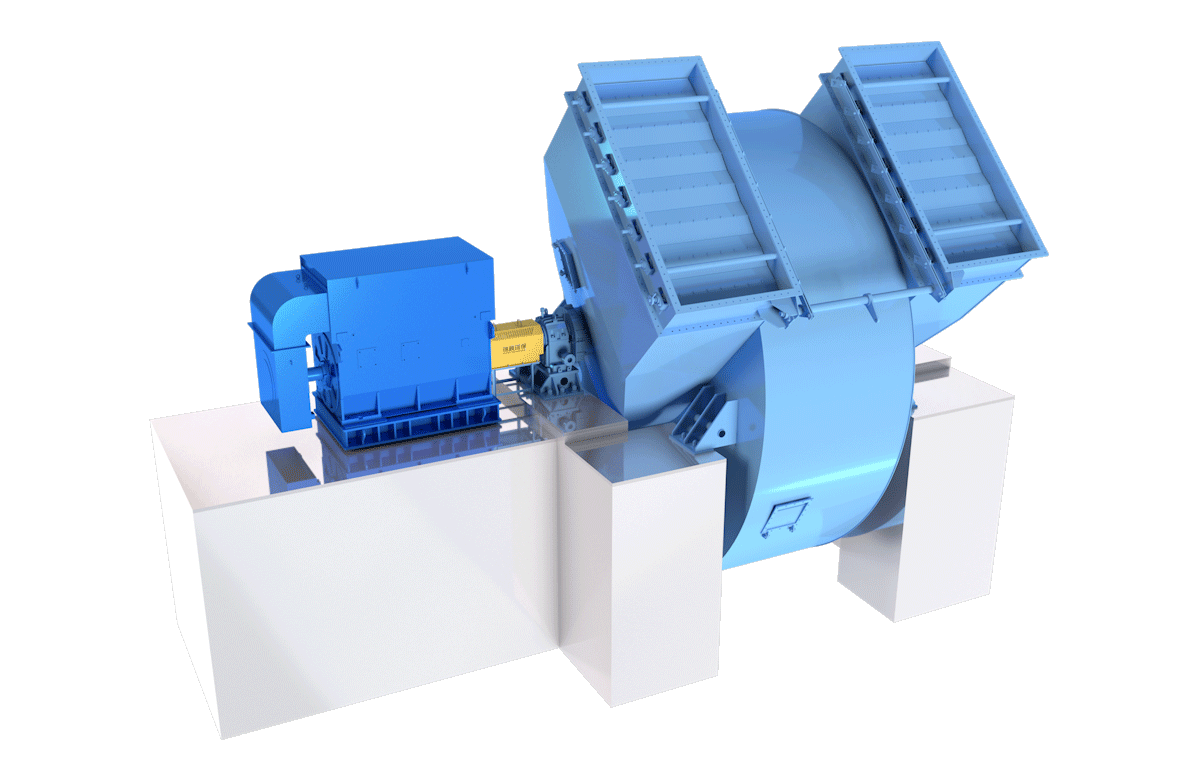

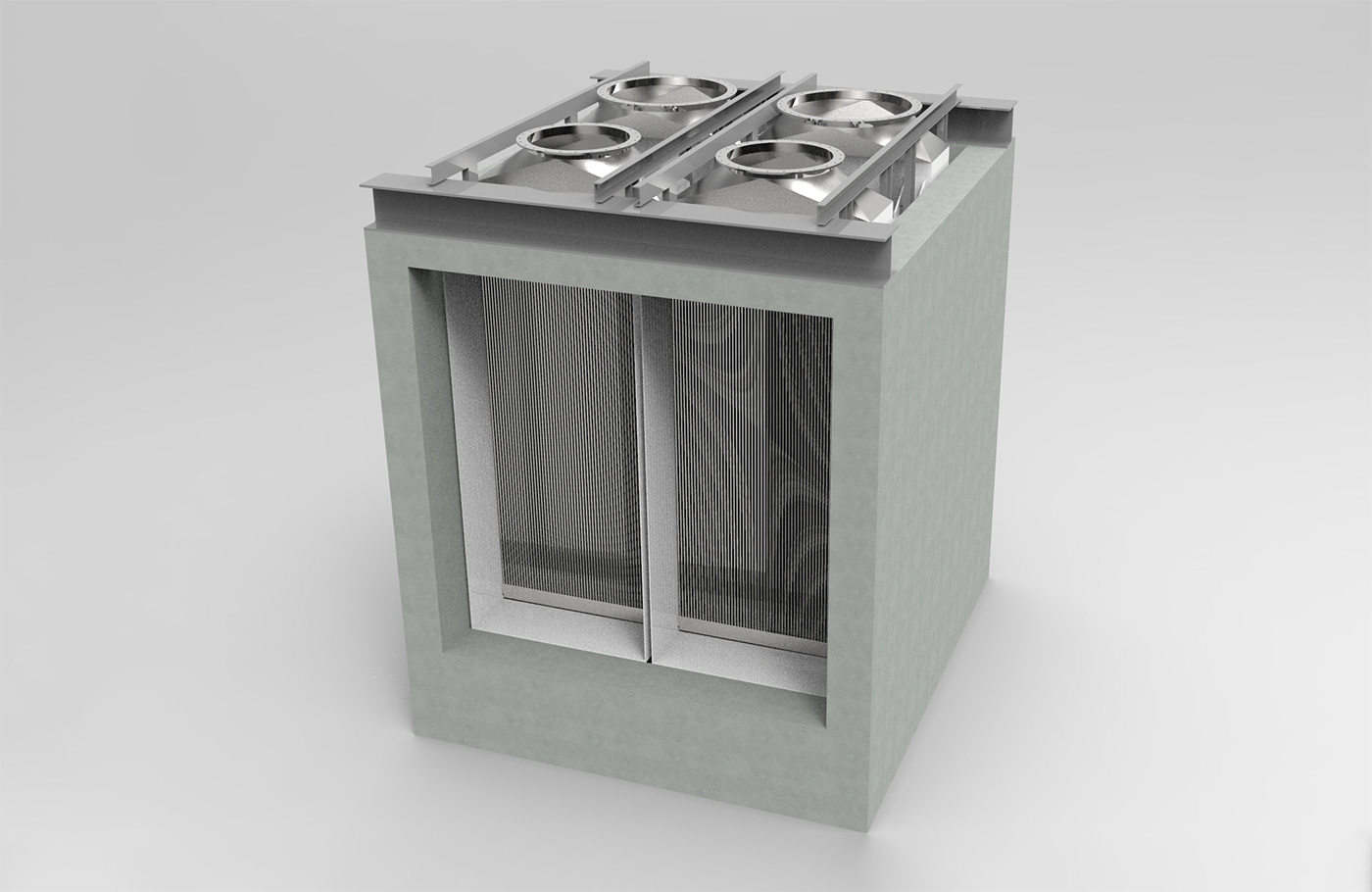

This technical transformation involves the steel-making and steel-rolling workshop of Anyang Iron and Steel II, with a total of 27 circulating water pumps in 12 systems. After the transformation, the main flow rate, pressure and other key indicators of all systems are not lower than before the technological transformation. The average operating efficiency of the pump reaches 83-84%, and the average power saving rate exceeds 31%. The transformation effect has been highly recognized by Anyang Iron and Steel leaders and users.

1. Project Profile

1.1 Enterprise Profile:

Anyang Iron and Steel Group Co., Ltd. was founded in 1958. After more than 50 years of development, it has become a modern iron and steel group with an annual steel production capacity of 10 million tons, which integrates mining and beneficiation, coking and sintering, steel smelting, steel rolling and mechanical processing, metallurgical construction, scientific research and development, information technology, logistics and transportation, international trade, real estate and other industries, and ranks among the top 100 of China's top 500 enterprises, henan Province, the largest fine plate and high-quality building materials production base.

1.2 Project Overview:

This technical transformation involves the steel-making and steel-rolling workshop of Anyang Iron and Steel II, with a total of 27 circulating water pumps in 12 systems. After the transformation, the main flow rate, pressure and other key indicators of all systems are not lower than before the technological transformation. The average operating efficiency of the pump reaches 83-84%, and the average power saving rate exceeds 31%. The transformation effect has been highly recognized by Anyang Iron and Steel leaders and users.

2. Transformation results

2.1 transformation before and after the data comparison:

3. Benefit analysis

According to the data of the National Development and Reform Commission, the production of 10000 kWh of electricity requires 3 tons of standard coal and 8.72 tons of CO2 emissions. The energy saving and environmental protection benefits generated by the project are (calculated at 8000 hours of operation per year and 0.6 yuan per kWh of electricity):

the average power saving rate is 31.2 percent;

The annual electricity saving is about 13.37 million kWh, and the direct economic benefit exceeds 8.02 million yuan;

It saves about 4,010 tons of standard coal per year and reduces CO2 emissions by more than 11,657 tons.

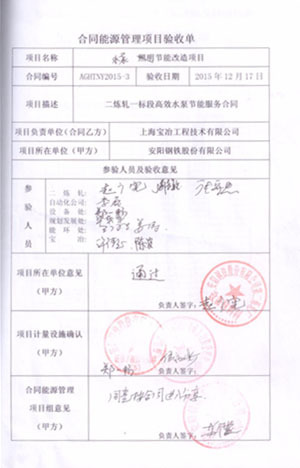

4. Acceptance report:

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us