Energy Saving Renovation Project of Circulating Water System of Bayer Material Technology (China) Co., Ltd.

Release time:

2022-04-07

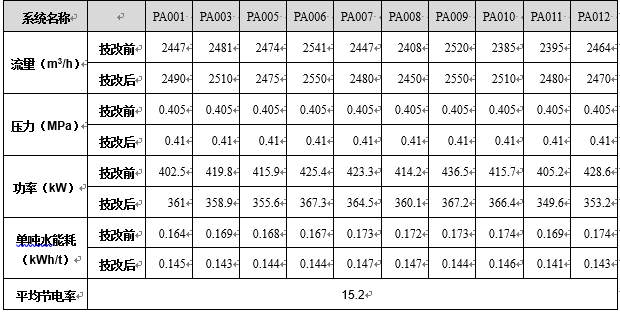

Bayer technical transformation project involves A547 system, the original system used in the pump for the German imported KSB water pump. This project has 10 technical renovation pumps, with an operating efficiency of 80%-82% before technical renovation and 88%-90% after technical renovation. According to the energy consumption per ton of water, the power saving rate is 15.2, the flow pressure and other indicators fully meet the production requirements, and the effect of technical transformation has been highly recognized by Bayer.

1. Project Profile

1.1 Enterprise Profile:

Germany's Bayer Group is one of the world's most well-known Fortune 500 (Fortune) companies, and ranks among the forefront of the industry in many fields such as material innovation, crop science and medicine and health care.

China is Bayer's second largest market in Asia, and Bayer is full of confidence in the development potential of China's future market. In November 2001, Bayer Group made a large-scale epoch-making investment in Shanghai Chemical Industrial Park and built a world-class integrated chemical base-Bayer Materials Technology (China) Co., Ltd. At the same time, sales of its Materials Innovation Group's high-performance products in China also increased significantly.

1.2 Project Overview:

Bayer technical transformation project involves A547 system, the original system used in the pump for the German imported KSB water pump. This project has 10 technical renovation pumps, with an operating efficiency of 80%-82% before technical renovation and 88%-90% after technical renovation. According to the energy consumption per ton of water, the power saving rate is 15.2, the flow pressure and other indicators fully meet the production requirements, and the effect of technical transformation has been highly recognized by Bayer.

2. Transformation results

2.1 transformation before and after the data comparison:

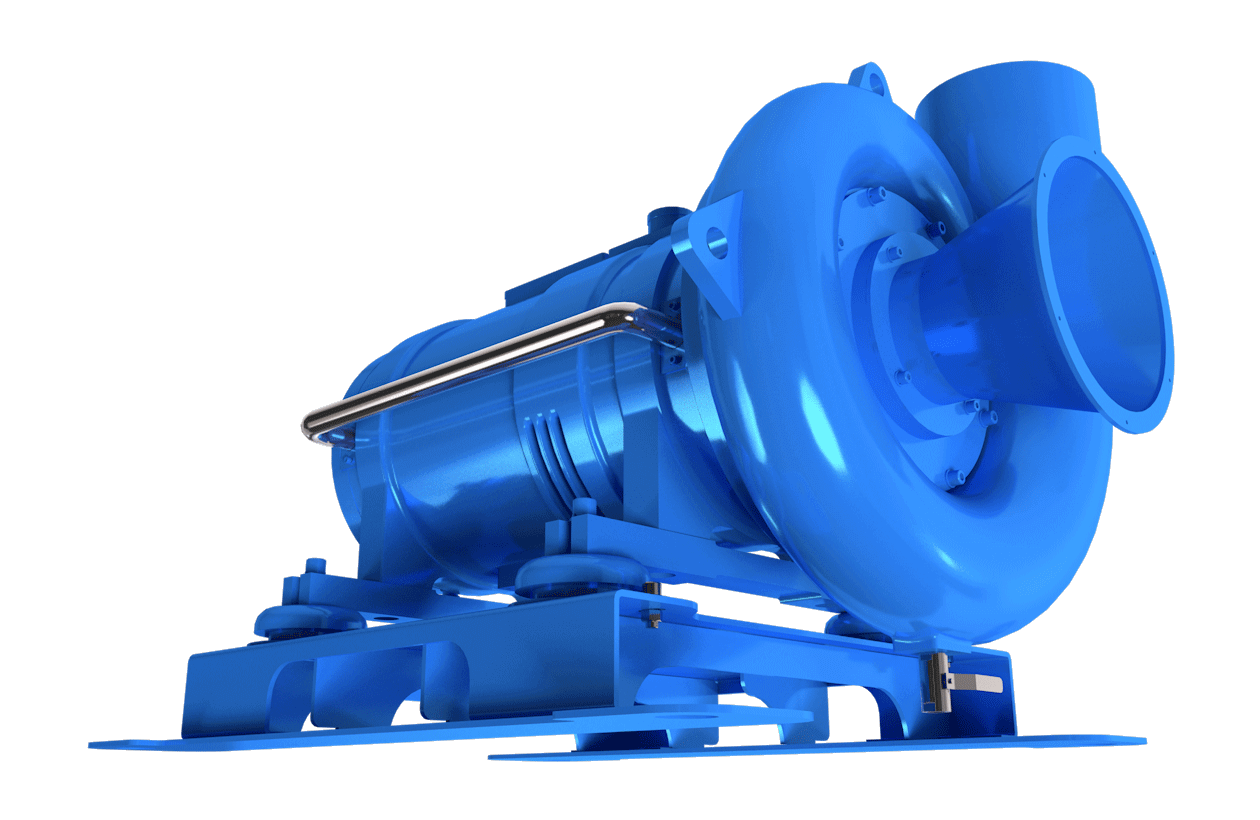

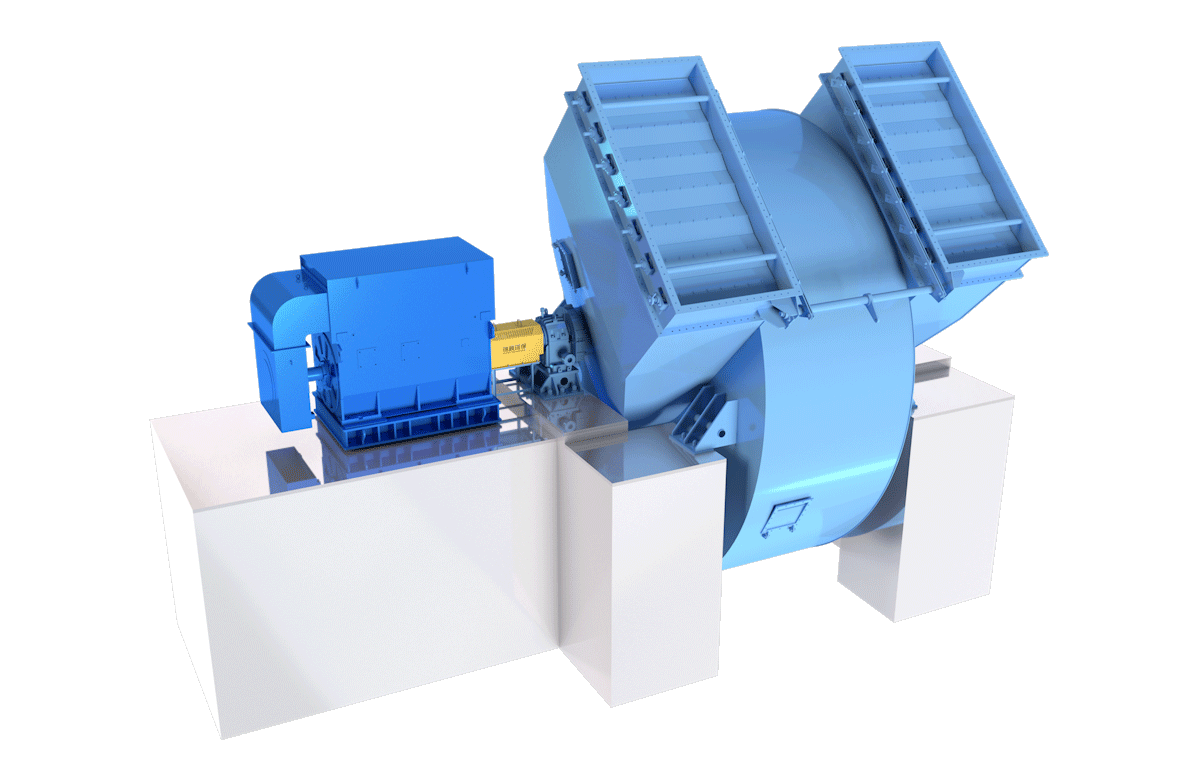

2.2 before and after the transformation of equipment photo contrast:

3. Benefit analysis

According to the data of the National Development and Reform Commission, the production of 10000 kWh of electricity requires 3 tons of standard coal and 8.72 tons of CO2 emissions. The energy saving and environmental protection benefits generated by the project are (calculated at 8000 hours of operation per year and 0.6 yuan per kWh of electricity):

>the average power saving rate is 15.2 percent;

>The annual electricity saving is about 4.67 million kWh, and the direct economic benefit exceeds 2.8 million yuan;

>About 1,401 tons of standard coal are saved each year, and CO2 emissions are reduced by more than 4,072 tons.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us