Sinoma Cement Co., Ltd. Fan Energy Saving Technical Transformation Project

Release time:

2022-04-07

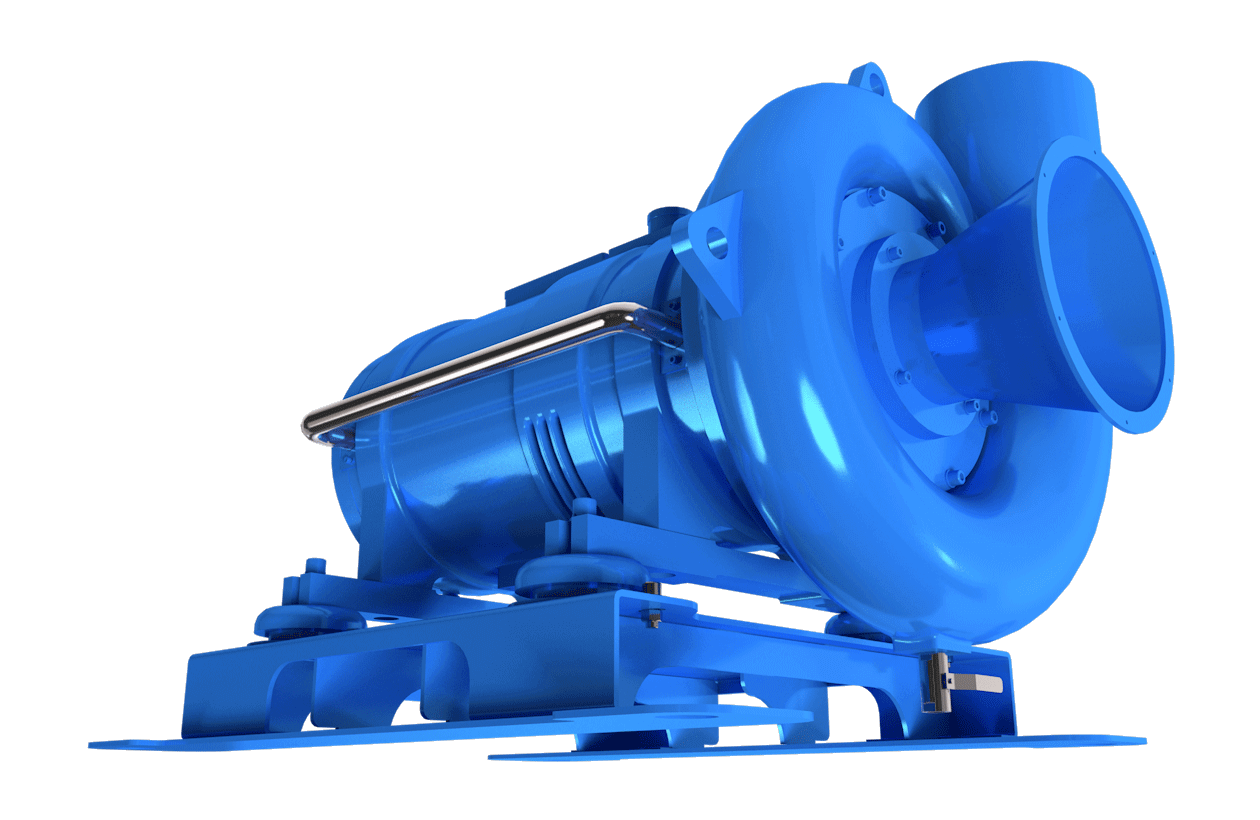

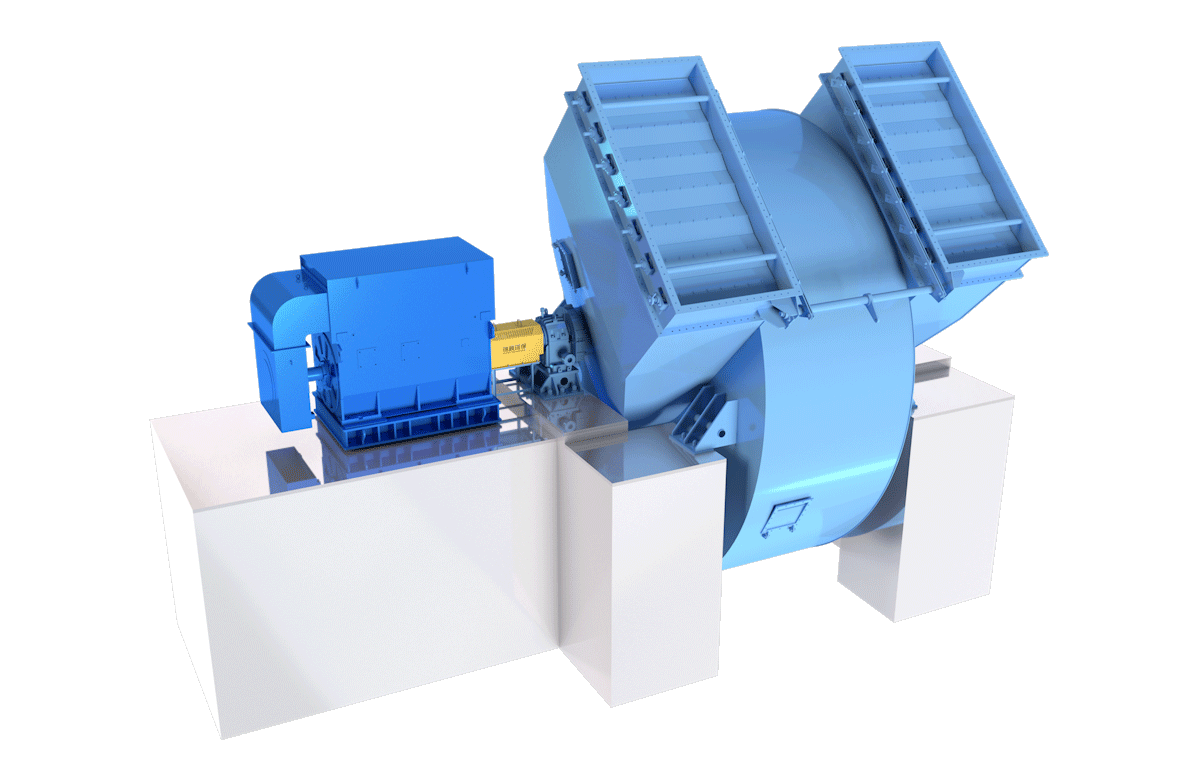

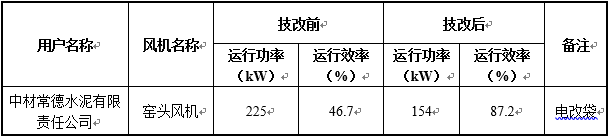

In response to the national call for "energy saving and emission reduction", Zhongcai Changde Cement has reduced chimney dust emissions and replaced the original electric dust removal equipment of kiln head fan with bag dust removal equipment. The system resistance will increase by 1000Pa to 1500Pa. Shanghai Rychen adopts high-efficiency fluid conveying technology and customizes "Rui Chang" high-efficiency and energy-saving fans, which can not only meet the needs of increasing wind pressure after changing electric bags, but also effectively reduce the operating power of kiln head fans. After the energy-saving technological transformation, the operating efficiency of the kiln head fan is as high as 87.21, and the operating power is reduced from 225KW before the transformation to 154KW. The customer has reported good results and plans to hand over other fans to Shanghai Rychen for further transformation.

Sinoma Cement Co., Ltd. was established on November 20, 2003 and is affiliated to China National Building Materials Group Co., Ltd., a central enterprise directly managed by the State-owned Assets Supervision and Administration Commission of the State Council.

At present, there are 9 cement enterprises in Shaanxi, Guangdong, Hunan, Jiangxi, Anhui, Jiangsu and Xinjiang, 14 new dry clinker cement production lines equipped with pure low-temperature waste heat power generation technology, 1 scientific research institute and 3 concrete production enterprises. The annual production capacity of cement is 25 million tons, that of concrete is 2.1 million tons, that of mechanism aggregate is 5 million tons, and that of concrete admixture is 30000 tons.

(1) Renovation Project of Kiln Head Fan of Sinoma Changde Cement 2500t/d Line

In response to the national call for "energy saving and emission reduction", Zhongcai Changde Cement has reduced chimney dust emissions and replaced the original electric dust removal equipment of kiln head fan with bag dust removal equipment. The system resistance will increase by 1000Pa to 1500Pa. Shanghai Rychen adopts high-efficiency fluid conveying technology and customizes "Rui Chang" high-efficiency and energy-saving fans, which can not only meet the needs of increasing wind pressure after changing electric bags, but also effectively reduce the operating power of kiln head fans. After the energy-saving technological transformation, the operating efficiency of the kiln head fan is as high as 87.21, and the operating power is reduced from 225KW before the transformation to 154KW. The customer has reported good results and plans to hand over other fans to Shanghai Rychen for further transformation.

technical reform before and after the comparison of parameters:

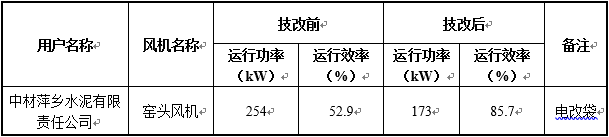

(2) Zhongcai Pingxiang Cement 2500t/d Line Kiln Head Fan Renovation Project

In response to the national call for "energy conservation and emission reduction", Sinoma Pingxiang Cement has reduced chimney dust emissions and replaced the original electric dust removal equipment of kiln head fan with bag dust removal equipment. The system resistance will increase by 1000Pa to 1500Pa. Shanghai Rychen adopts high-efficiency fluid conveying technology and customizes "Rui Chang" high-efficiency and energy-saving fans, which can not only meet the needs of increasing wind pressure after changing electric bags, but also effectively reduce the operating power of kiln head fans. After the energy-saving technological transformation, the operating efficiency of the kiln head fan is as high as 85.7, and the operating power is reduced from 254KW/h before the transformation to 173KW/h. The customer has reported good results and plans to hand over other fans to Shanghai Rychen for further transformation.

technical reform before and after the comparison of parameters:

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us