Hebei Jinyu Dingxin Cement Co., Ltd. Coal Mill Fan Reconstruction Project

Release time:

2022-04-07

The operating efficiency of the original 4000t/d coal mill fan is 68.8%, and the operating efficiency is low. In order to improve the air volume, the original fan needs to be technically modified. After the renovation of our company, the flow rate has been greatly improved compared with that before the renovation, the equipment is stable in operation, and the fan operation efficiency has reached 82.7, which has been unanimously recognized by the senior management and leaders of Jinyu Dingxin.

Company Profile

Hebei Jinyu Dingxin Cement Co., Ltd. has an annual clinker production capacity of 7.5 million tons, a high-quality and high-grade cement production capacity of 10 million tons, an annual output of 900000 cubic meters of concrete and 2 million tons of sand and gravel aggregate. The company has three production branches, a mining company and a Lingang Jinyu subsidiary, two new dry clinker cement production lines with a daily output of 2000 tons and three new dry clinker cement production lines with a daily output of 4000 tons, including a national energy-saving demonstration line with a daily output of 4000 tons and a second-gear short kiln, which represents the best level of international energy consumption.

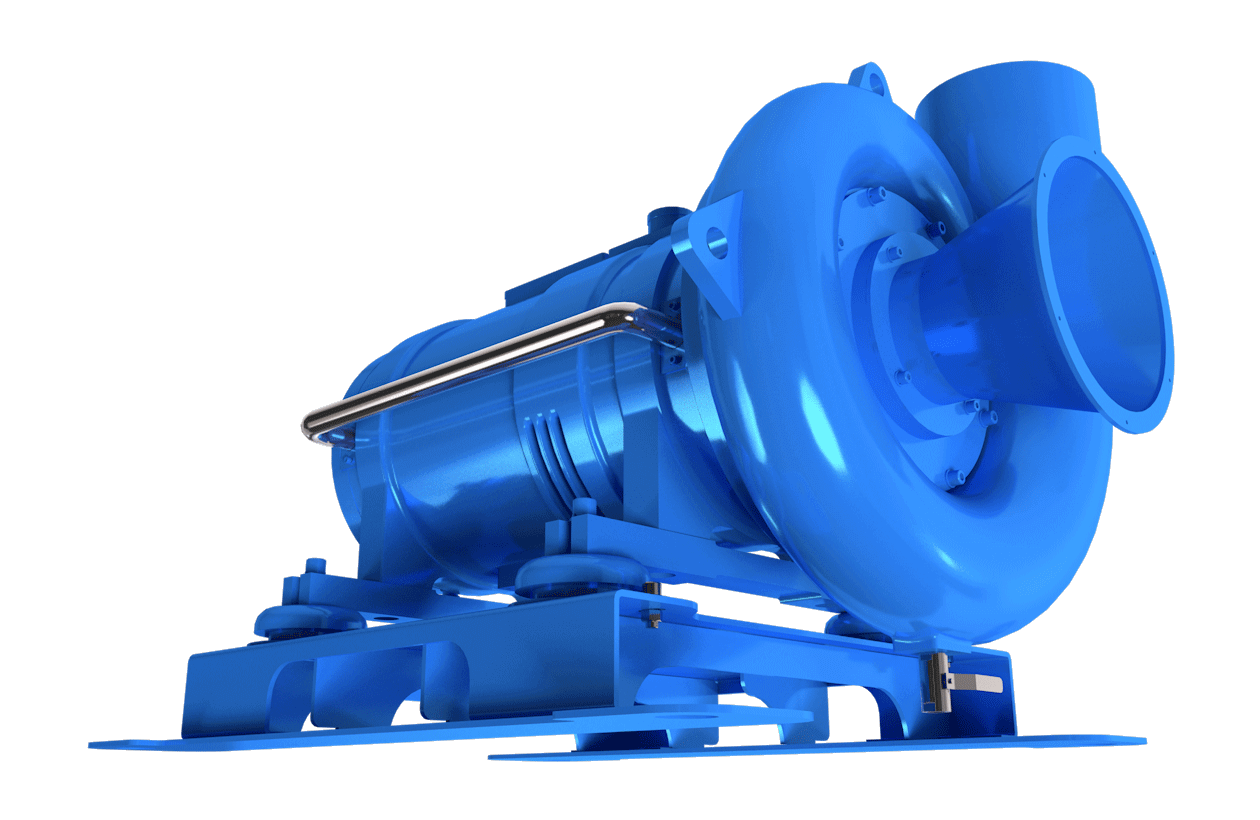

Technical Reform Project of Coal Mill Fan

Project Profile

The operating efficiency of the original 4000t/d coal mill fan is 68.8%, and the operating efficiency is low. In order to improve the air volume, the original fan needs to be technically modified. After the renovation of our company, the flow rate has been greatly improved compared with that before the renovation, the equipment is stable in operation, and the fan operation efficiency has reached 82.7, which has been unanimously recognized by the senior management and leaders of Jinyu Dingxin.

Comparison of parameters before and after technological transformation

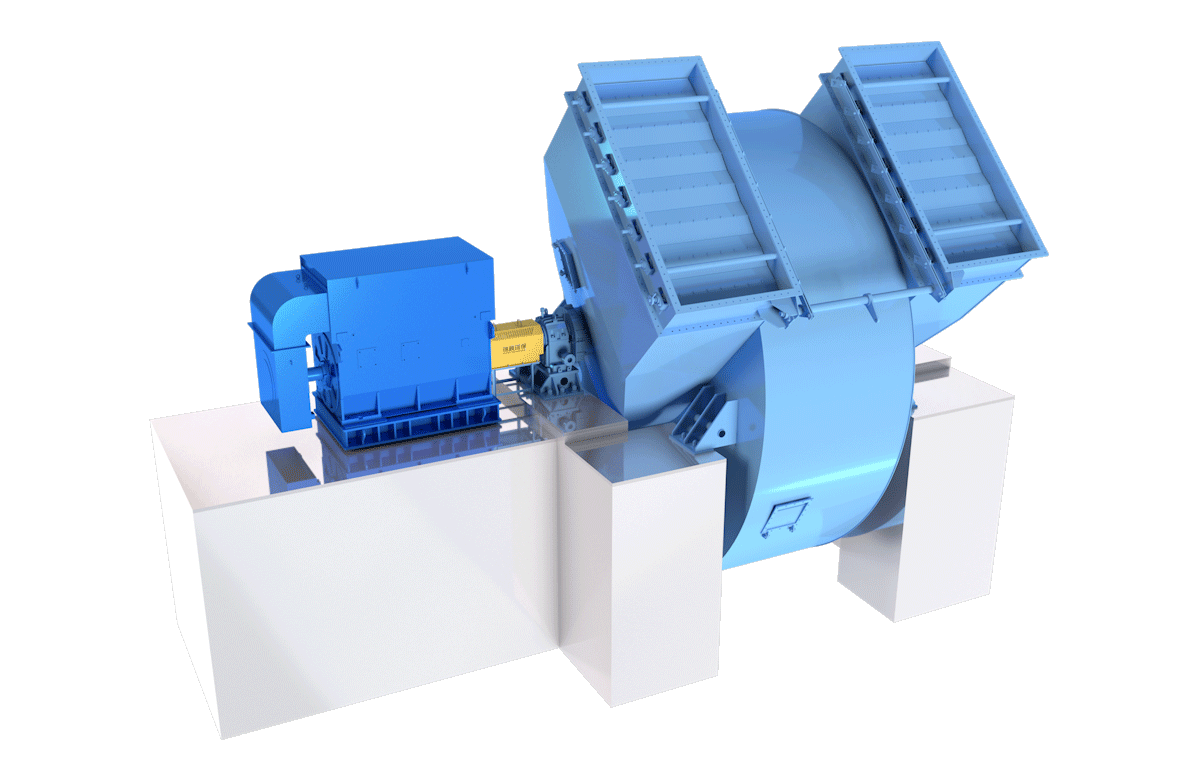

Technical improvement project of high temperature and kiln tail fan

Project Profile

In 2019, Hebei Jinyu Dingxin Cement Second Branch carried out the kiln line "solid waste medium temperature SCR" environmental protection transformation project, which greatly increased the air volume and pressure required by the system, and the output of the original high-temperature fan and kiln tail fan was insufficient, so the fan needs to be upgraded to meet the new production demand.

After bidding, Shanghai Rychen won the bid with its technical advantages: accurately calibrating the on-site working conditions, tailoring high-efficiency and energy-saving fans according to customer needs, effectively improving the operating efficiency of the fans, and the required matching motor power is far less than that of other manufacturers, thus meeting the new process requirements and realizing the energy-saving effect.

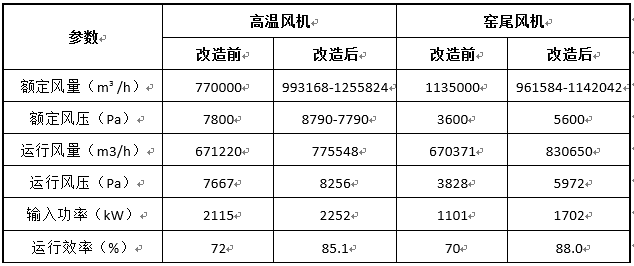

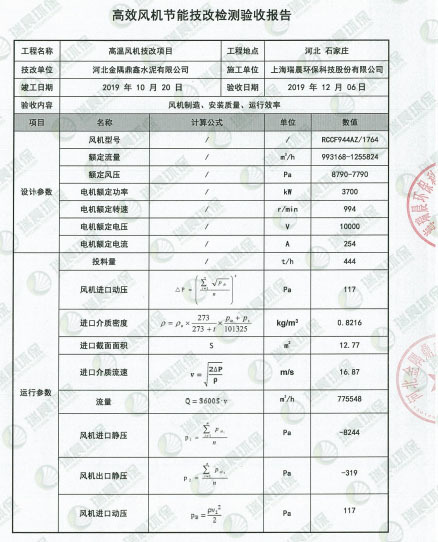

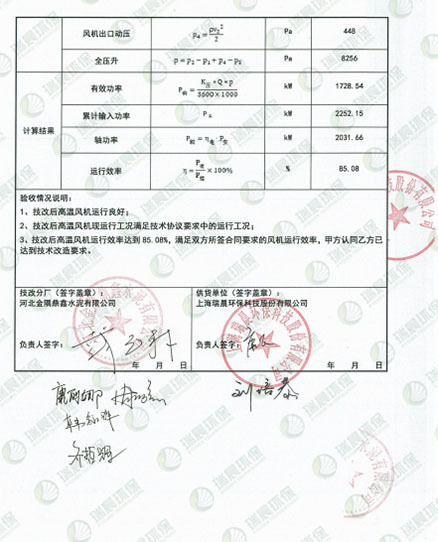

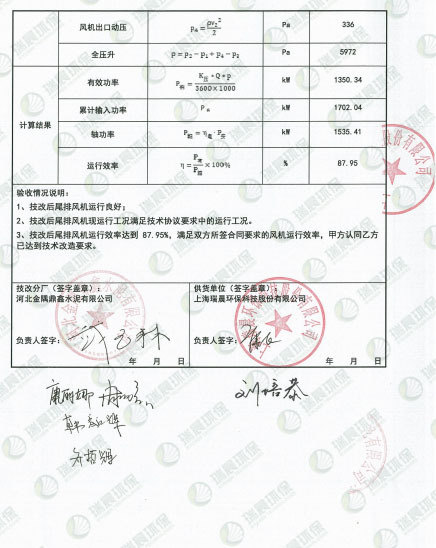

Comparison of parameters before and after technological transformation

Shanghai Rychen customized a high-efficiency and energy-saving fan for Jinyu Dingxin. After the renovation, the rated air volume of the high-temperature fan increased from 770000 m/h to 1.25 million m/h, the rated air pressure of the kiln tail fan increased from 3600Pa to 5600Pa, and the operating air volume and air pressure also increased significantly (see table). The operating efficiency was higher than 85%, which met the environmental protection requirements and achieved the energy-saving effect.

Acceptance Report

The renovation project was completed in October 2019 and successfully accepted in December 2019, which was unanimously recognized by the senior management and leaders of Jinyu Dingxin.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us