Southern Cement Co., Ltd. Fan Energy Saving Technical Transformation Project

Release time:

2022-04-07

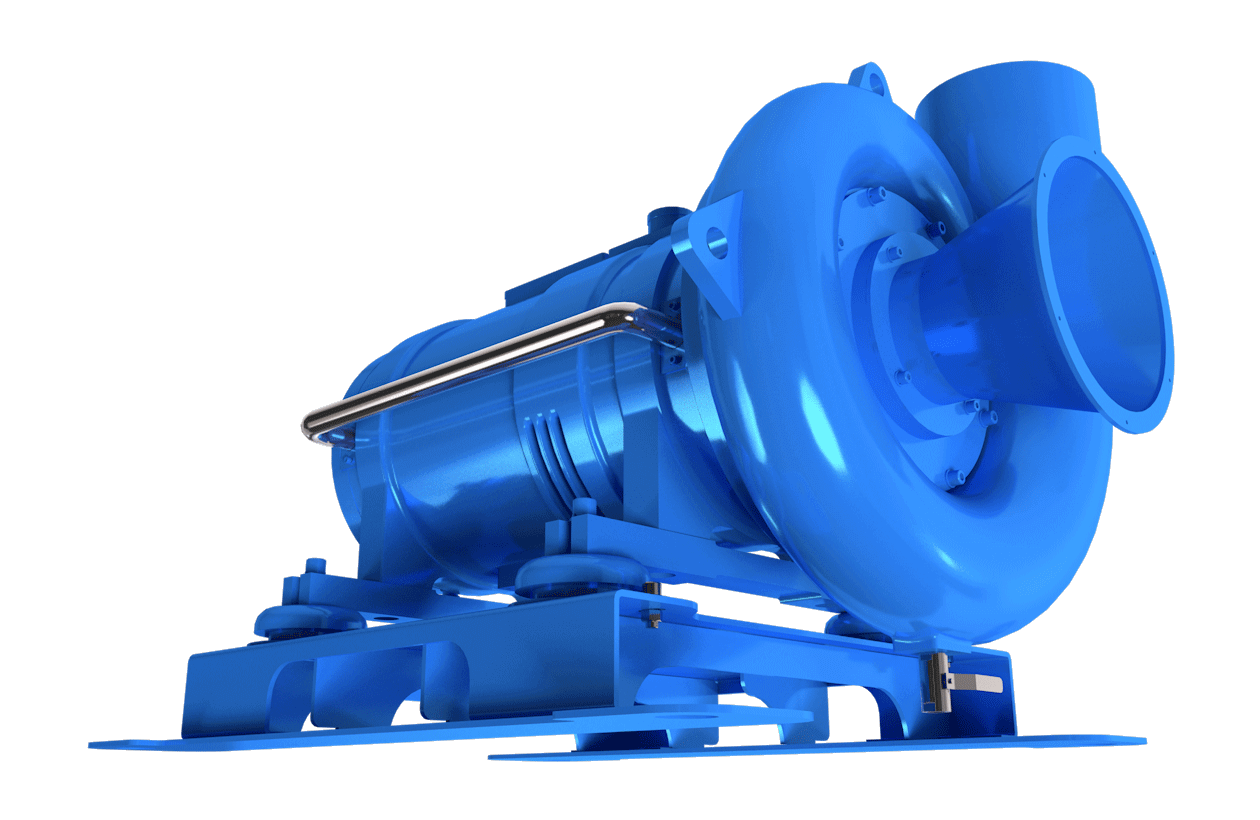

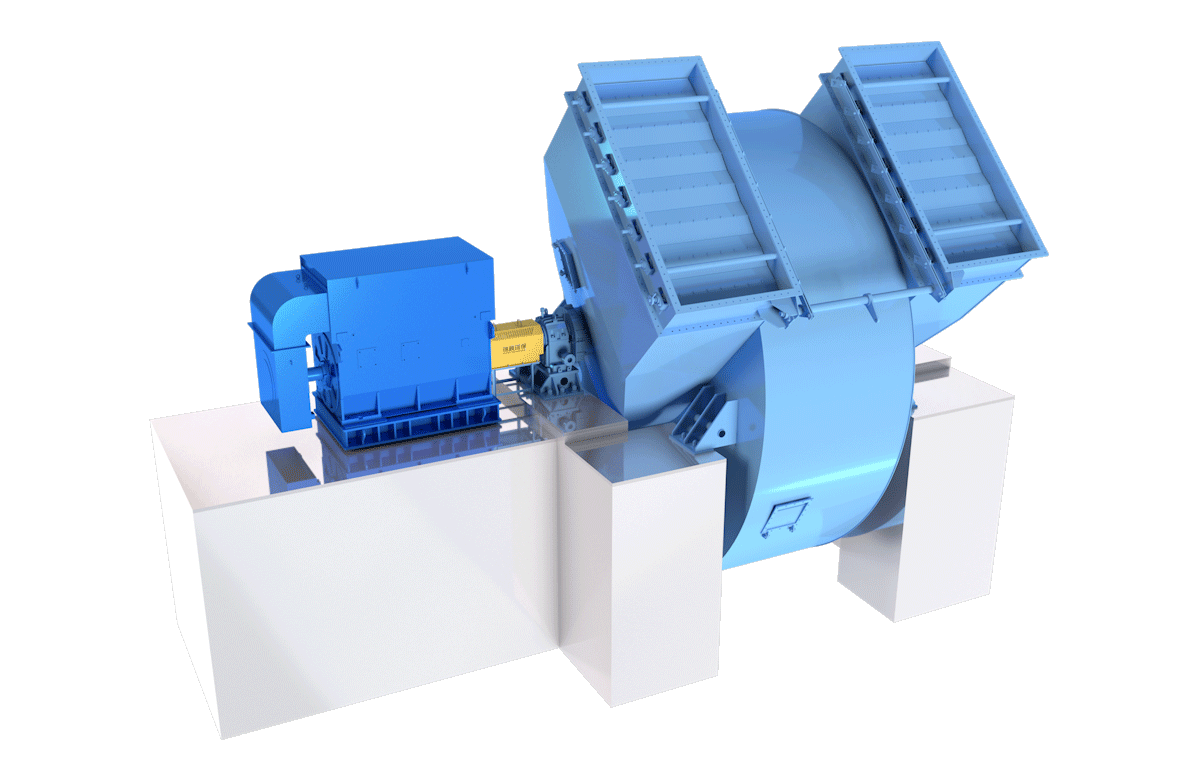

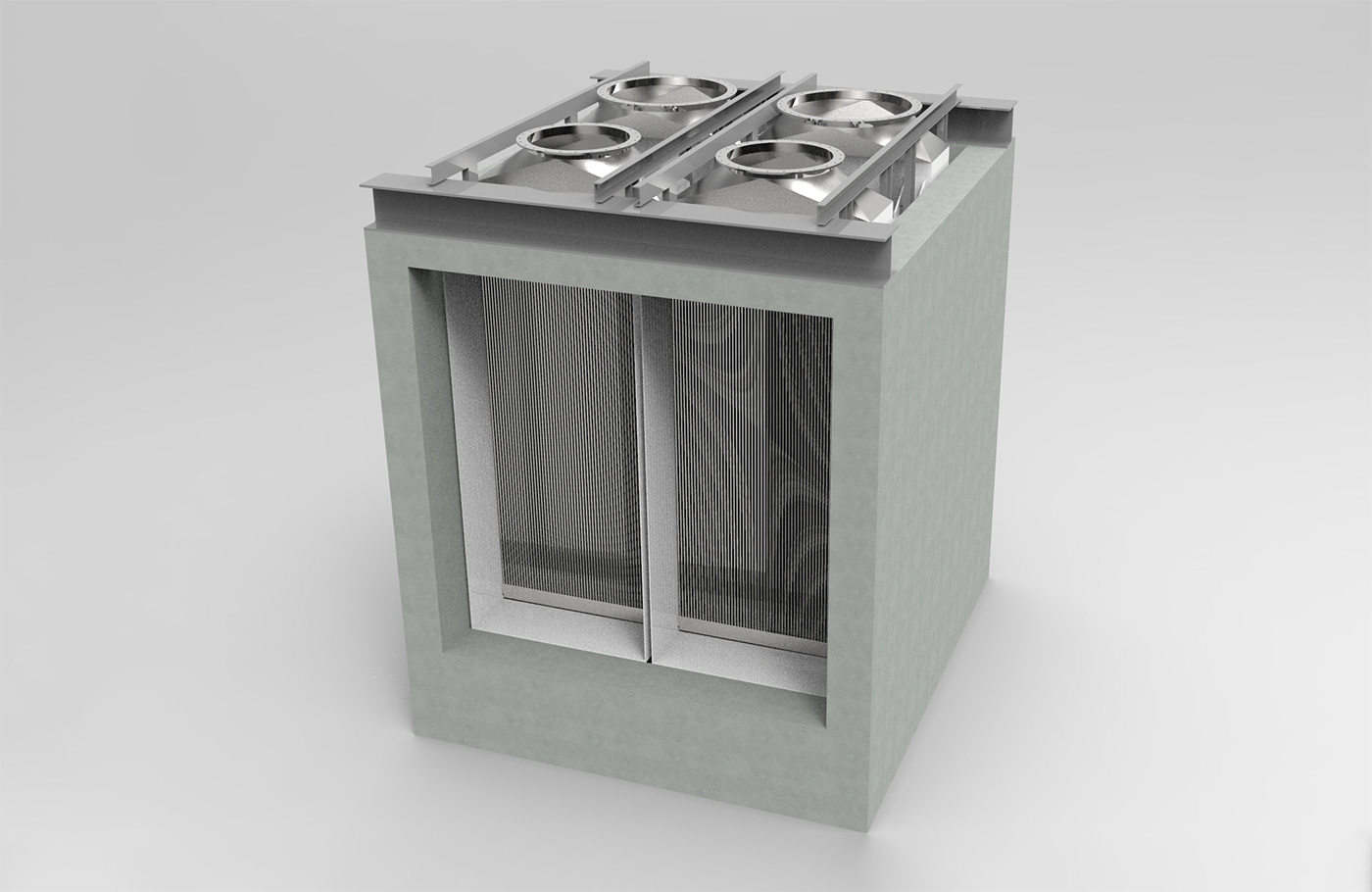

Jiangxi Southern Cement responded to the national call for environmental protection, reduced dust emissions, and replaced the original electric dust removal equipment at the kiln end of each branch plant with bag dust removal equipment. The system resistance will increase by 1000Pa to 1500Pa. Shanghai Rychen adopts high-efficiency fluid conveying technology and customized "Rui Chang" high-efficiency energy-saving fan, which can not only meet the need of increasing wind pressure after changing electric bags, but also effectively reduce the increase of production cost. After technological transformation, the operating efficiency of the three high-efficiency fans is higher than 80%, and the increase in power consumption per ton is lower than 1.5kWh, meeting the requirements of Southern Group.

Southern Cement Co., Ltd. is one of the core enterprises in the cement business segment of China Building Materials Co., Ltd., with 123 cement enterprises, 185 commercial mixed enterprises, clinker production capacity of 0.125 billion tons, cement production capacity of 0.167 billion tons, commercial mixed production capacity of 0.192 billion square meters, cement, commercial mixed comprehensive production capacity are ranked first in the country.

Jiangxi Southern Bag Dust Removal Supporting Fan Renovation Project

Jiangxi Southern Cement responded to the national call for environmental protection, reduced dust emissions, and replaced the original electric dust removal equipment at the kiln end of each branch plant with bag dust removal equipment. The system resistance will increase by 1000Pa to 1500Pa. Shanghai Rychen adopts high-efficiency fluid conveying technology and customized "Rui Chang" high-efficiency energy-saving fan, which can not only meet the need of increasing wind pressure after changing electric bags, but also effectively reduce the increase of production cost. After technological transformation, the operating efficiency of the three high-efficiency fans is higher than 80%, and the increase in power consumption per ton is lower than 1.5kWh, meeting the requirements of Southern Group.

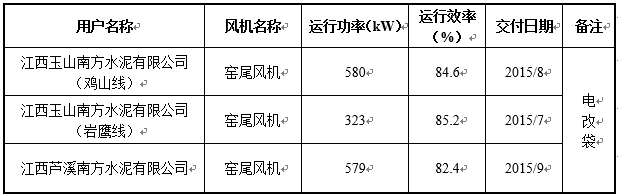

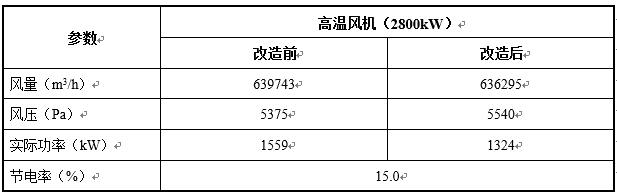

Comparison before and after technical reform:

Jiangxi Shanggao South Cement Co., Ltd. High Temperature Fan Renovation Project

Jiangxi Shanggao South Cement Co., Ltd. has a 4500t/d cement clinker new dry production line, which was officially put into operation in July 2010. The company has 352 employees, with an annual output of 1.7 million tons of high-grade cement and more than 230 million tons of clinker. This project involves the high-temperature fan of 4500t/d production line. The original fan was produced by Siping Blower Factory. The on-site operation efficiency is less than 70%, and the energy consumption of the fan is relatively high. The company's leaders and energy-saving manufacturers have communicated and communicated for many times, and finally Shanghai Rychen was chosen for renovation. After the renovation, the operating efficiency reached 83.44% and the operating power decreased by 235kW, meeting the contract requirements. The acceptance of the project was successfully completed in August 2017.

technical reform before and after the comparison of parameters:

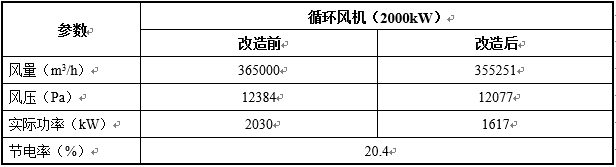

Renovation Project of Circulating Fan of Hunan Shaofeng Southern Cement Co., Ltd

Hunan Shaofeng Southern Cement Co., Ltd., formerly known as Xiangxiang Cement Factory, became a member enterprise of Hunan Southern Cement Co., Ltd. in 2008. It has two cement clinker production lines with a daily output of 2500t/d and 5000t/d, and is equipped with a waste heat power generation system with an installed capacity of 9000 kW. Shanghai Rychen was technically approved by Hunan Shaofeng Southern Cement Co., Ltd. and carried out energy-saving renovation on the raw mill circulating fan of its 2500t/d production line. The renovation was completed in September 2017 and delivered perfectly. The stable operation of the equipment, the power saving rate of up to 20.4, far higher than the agreed value of the agreement, Shaofeng South high-level praise.

technical reform before and after the comparison of parameters:

Anhui Dajiang Co., Ltd. Line 2 High Temperature Fan Renovation Project

With the increasingly fierce competition in the cement industry, it is imperative to save the cost of the production line. Anhui Dajiang Co., Ltd. actively responded to the call of national energy conservation and environmental protection, and carried out the technical reform of fan energy conservation. Shanghai Rychen was technically approved by Anhui Dajiang Co., Ltd. to carry out energy-saving transformation of its 2-line high-temperature fan, and completed the transformation in August 2017. The equipment operated stably and the energy-saving benefits were significant.

technical reform before and after the comparison of parameters:

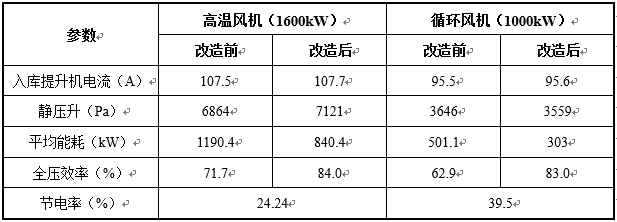

Renovation Project of High Temperature Fan and Circulating Fan of Anhui Langxi Southern Cement Co., Ltd.

Langxi South Co., Ltd. produces 2500 tons of cement clinker per day, with an annual output of 850000 tons of cement clinker. Under the industry trend of energy saving and consumption reduction, Langxi Southern Cement handed over its company's high-temperature fan and circulating fan to our company for transformation. After the transformation, under the same working conditions, the power saving rate of the high temperature fan reaches 24.24, and the power saving rate of the circulating fan reaches 39.51. Greatly reduce production costs and enhance competitiveness.

technical reform before and after the comparison of parameters:

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us