Energy Saving Renovation Project of Circulating Water System of Shanghai Meishan Iron and Steel Co., Ltd.

Release time:

2022-04-07

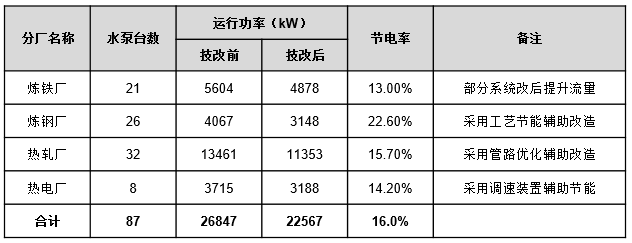

This project involves ironmaking plant, steel plant and hot rolling plant, a total of 87 water pumps, the scope of the transformation includes improving the hydraulic performance of the pump, optimize the resistance characteristics of the pipe network. After the transformation, the key indicators such as flow and pressure fully meet the production requirements, and the average power saving rate reaches 16%, which has been highly recognized by Meishan Iron and Steel Co., Ltd. and gradually promoted in the whole plant of Meishan Iron and Steel Co., Ltd.

1. Project Profile

1.1 Enterprise Profile:

Shanghai Meishan Iron and Steel Co., Ltd. is a subsidiary of Baoshan Iron and Steel Co., Ltd. It is located in the southwest suburb of Nanjing, facing the golden waterway of the Yangtze River in the north, Ningma Expressway, the third Nanjing Yangtze River Bridge and Ningwu Railway in the east, and the water and land transportation is very convenient. After 37 years of construction and development, it has formed a modern large-scale iron and steel complex with a comprehensive production capacity of nearly 7.6 million tons of steel and iron, integrating sintering, coking, ironmaking, steelmaking and hot rolling.

1.2 Project Overview:

This project involves ironmaking plant, steel plant and hot rolling plant, a total of 87 water pumps, the scope of the transformation includes improving the hydraulic performance of the pump, optimize the resistance characteristics of the pipe network. After the transformation, the key indicators such as flow and pressure fully meet the production requirements, and the average power saving rate reaches 16%, which has been highly recognized by Meishan Iron and Steel Co., Ltd. and gradually promoted in the whole plant of Meishan Iron and Steel Co., Ltd.

2. Transformation results

2.1 transformation before and after the data comparison:

2.2 before and after the transformation of equipment photo contrast:

3. Process energy saving

In view of the process characteristics of 3#RH smelting process in which the condensate water is discontinuous and the water consumption of different varieties and specifications is different, the process energy-saving transformation is added on the basis of high-efficiency water pump. According to energy consumption statistics, from January to October 2018, the cumulative power saving was 3.567 million degrees, with a cumulative average energy saving rate of 50.6.

4. Benefit analysis

According to the data of the National Development and Reform Commission, the production of 10000 kWh of electricity requires 3 tons of standard coal and 8.72 tons of CO2 emissions. The energy saving and environmental protection benefits generated by the project are (calculated at 8000 hours of operation per year and 0.6 yuan per kWh of electricity):

>Average power saving rate is 16%;

>The annual electricity saving is about 34.24 million kWh, and the direct economic benefit exceeds 20.54 million yuan;

>About 10,272 tons of standard coal are saved each year and more than 29,857 tons of CO2 are reduced.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us