Energy efficient technology

Release time:

2024-06-20

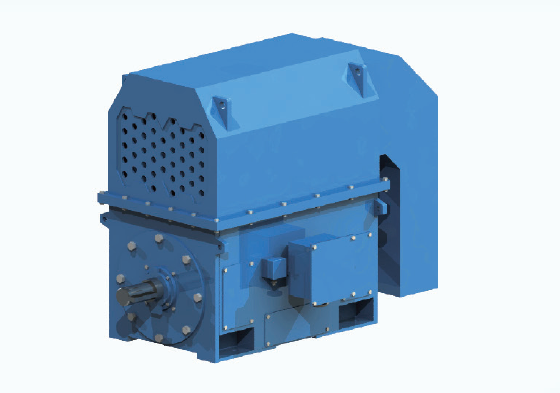

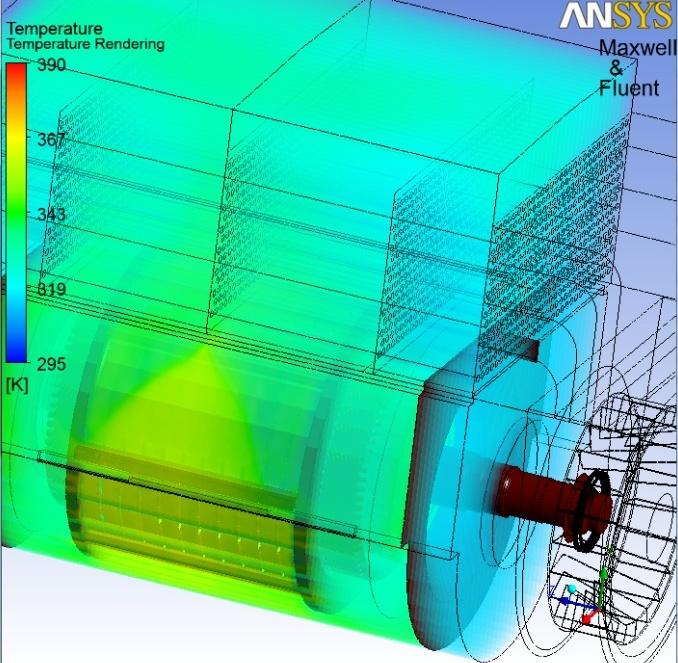

Implement an ultra-thin insulation system to improve the insulation capacity of the motor, increase the motor slot occupancy rate, reduce stator resistance, minimize stator copper loss, and enhance motor efficiency.

Implement an ultra-thin insulation system to improve the insulation capacity of the motor, increase the motor slot occupancy rate, reduce stator resistance, minimize stator copper loss, and enhance motor efficiency.

Measures to reduce iron loss, mainly including the use of low-loss high-quality cold-rolled silicon steel sheet, reduce the eddy current loss of the motor; adjust the slot shape, choose a reasonable magnetic flux density, reduce the fundamental wave iron loss; increase the length of the core, reduce the magnetic flux density to reduce the loss; improve the quality of core manufacturing, to ensure the insulation of the surface of the silicon steel sheet and other measures.

The reasonable groove shape is adopted, the coil structure is optimized, the magnetic flux leakage is reduced, the additional loss is reduced, and the motor efficiency is improved.

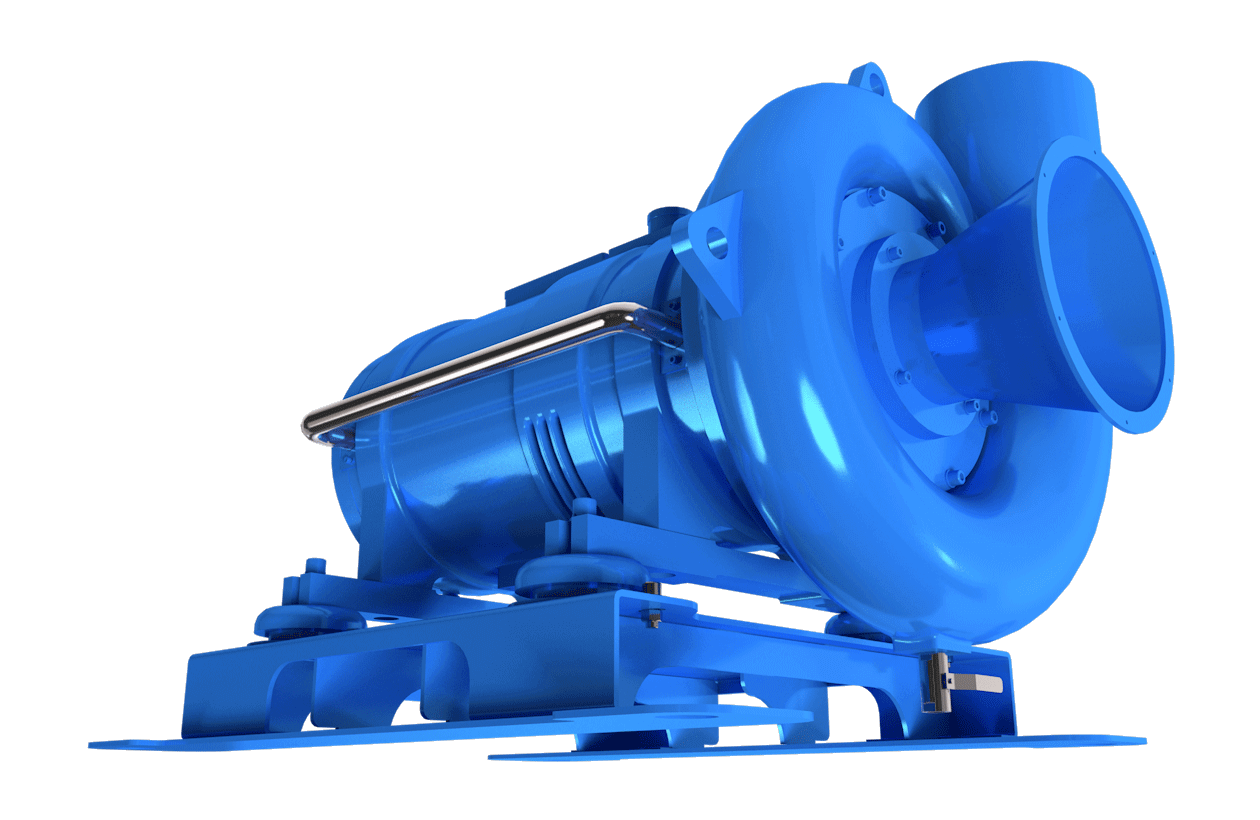

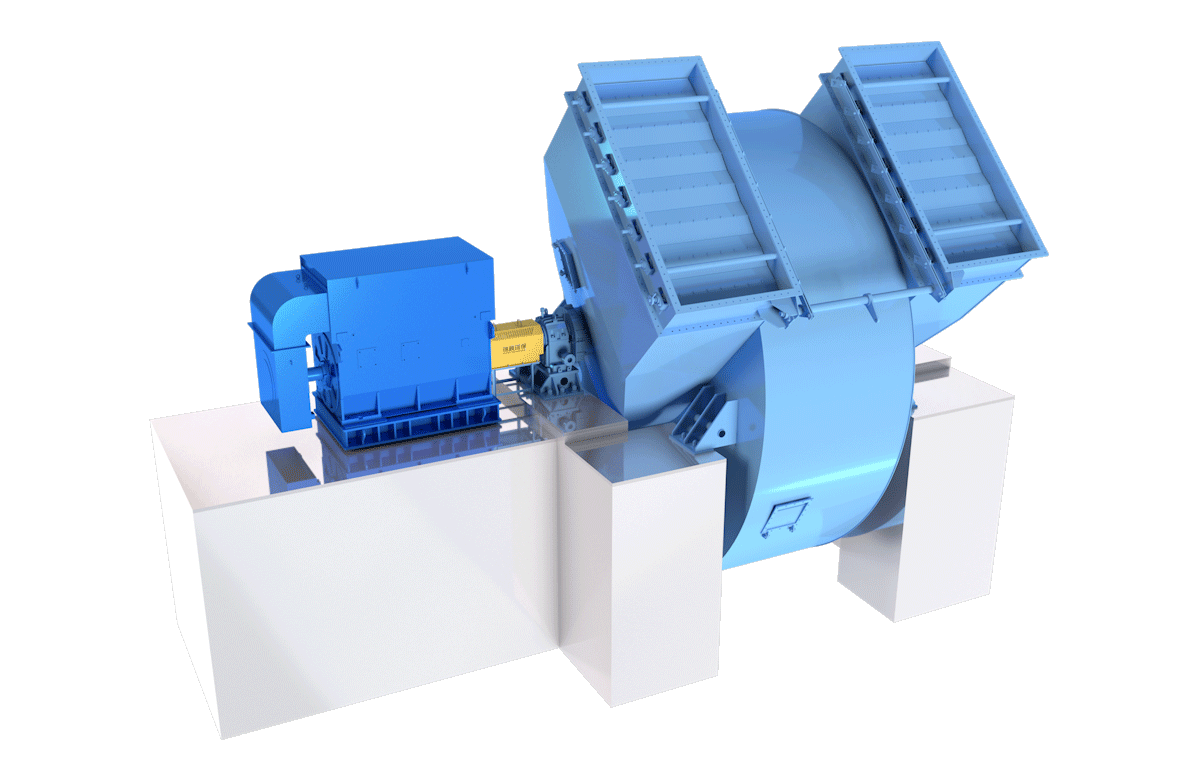

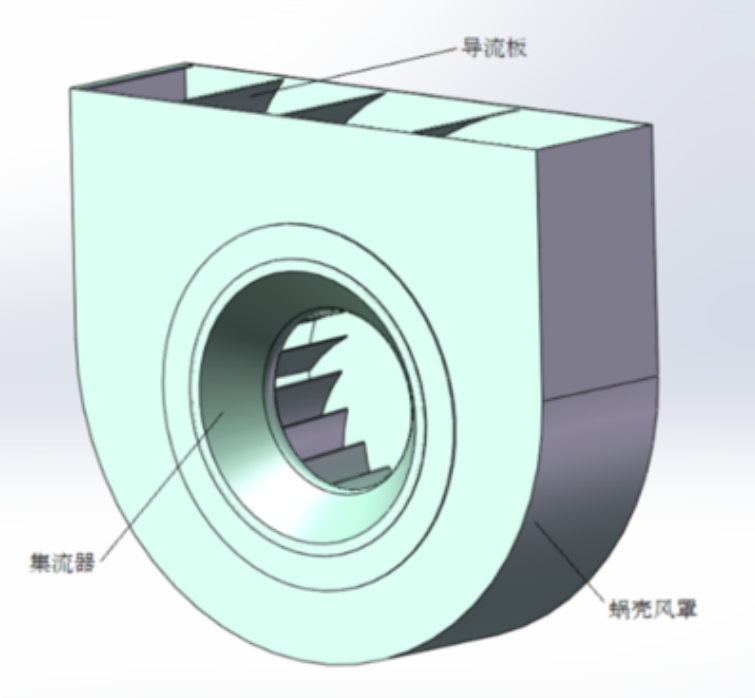

The measures to reduce mechanical loss mainly include high-efficiency volute fan structure and reasonable air path, improving blade surface roughness, smooth air flow, improving fan efficiency and reducing wind friction consumption. Select high-quality low-friction bearings and grease to reduce friction loss; Improve the accuracy of shape and position tolerance, ensure the assembly quality of the whole motor, and reduce friction loss.

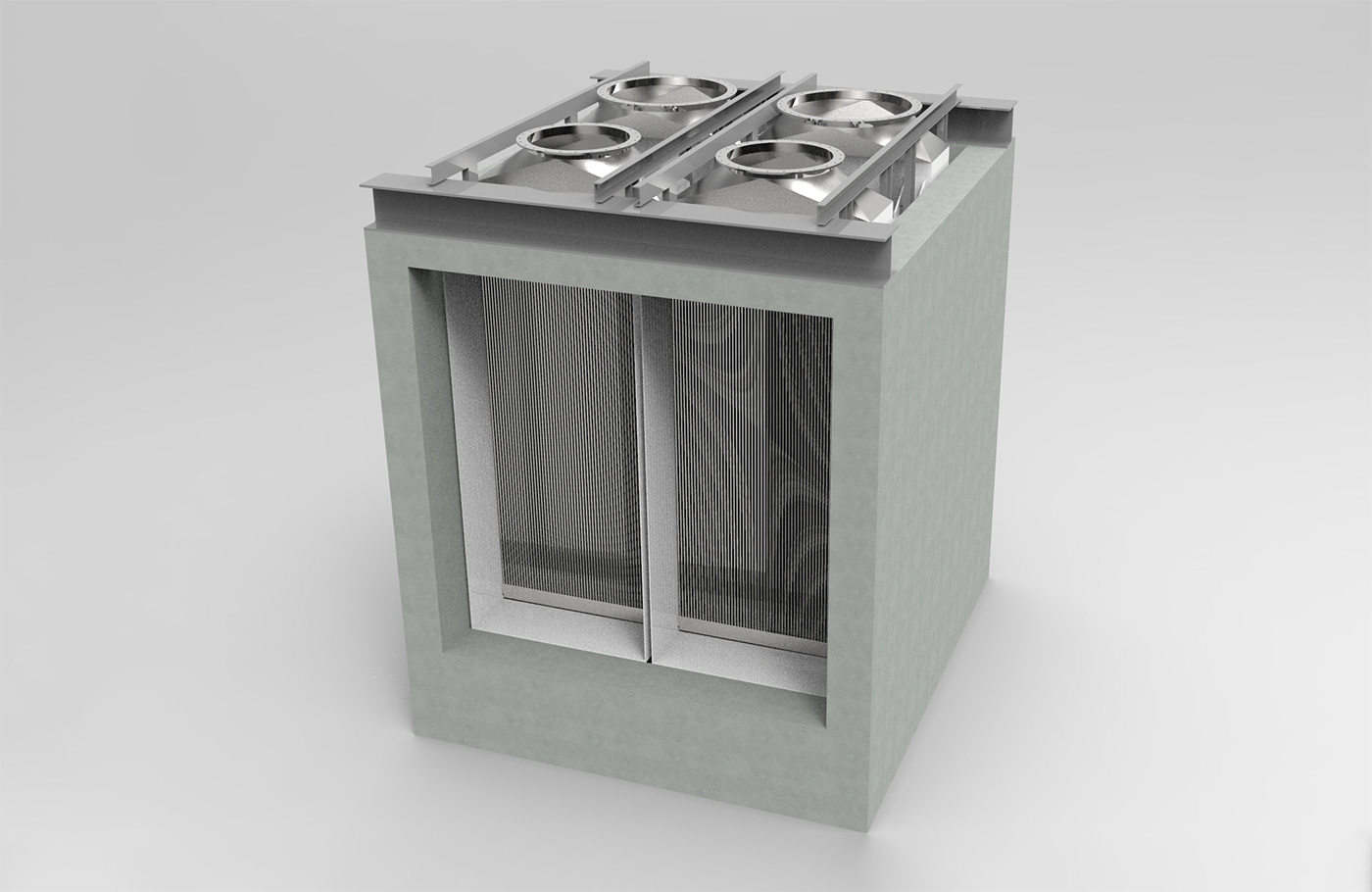

Stray losses can be reduced by optimizing the design and process. The design adopts optimized air gap, low harmonic winding, optimized slot fit, etc. In the process, the rotor slot is insulated to reduce the high-frequency transverse current loss of the rotor, and the air gap is replaced by punching out the air gap to reduce the high-frequency loss of the rotor surface. In addition, the motor end cover and other solid parts can be made of non-magnetic materials to limit the eddy current loss caused by the leakage magnetic field.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us