Technical Transformation Project of Circulating Fan of Sichuan Huaying Tay Cement Co., Ltd.

Release time:

2022-04-07

2019.11

Taiwan Cement takes "environmental protection, energy and cement" as its three core undertakings, and is committed to creating a circular economy of "zero waste, zero pollution and zero emission" and creating new value for sustainable enterprises. In Taiwan, Yunnan, Sichuan, Guangdong, Guangxi, Chongqing, Guizhou, Hunan and other places, there are many cement kiln production lines.

In order to realize the corporate vision, Taiwan Cement has been seeking cooperation with innovative enterprises of energy conservation and environmental protection. Its business philosophy coincides with Ruichen Environmental Protection's pursuit of innovative energy conservation methods. The renovation of the circulating fan of the 4000t/d clinker production line of Sichuan Huaying Taili Cement Co., Ltd. is undertaken by Ruichen Environmental Protection. Ruichen Environmental Protection has tailored solutions to the problems of high energy consumption, serious wear, vibration and noise of the original fan. The cooperation between the two parties was carried out smoothly and the renovation project was successfully completed.

Technical Reform Problems and Solutions

Problem 1: The original fan has low operating efficiency and high energy consumption

Solution: in-depth understanding of the field conditions, test fan operating parameters, the use of high-efficiency pneumatic model, tailor-made "Rui Chang" high-efficiency energy-saving fan.

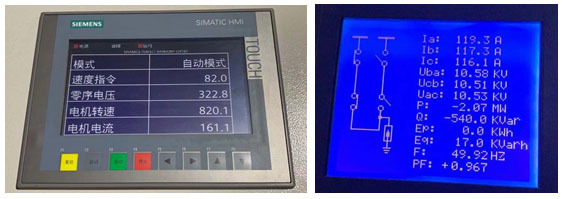

Transformation effect: After the transformation, the operating efficiency of the fan is 83.7%, the motor current is obviously reduced, and the energy saving rate is 30.7% according to the energy consumption statistics.

Energy consumption before modification

Energy consumption after modification

Problem two: fan impeller wear serious(Surfacing welding is basically once every six months, which increases maintenance costs. The shell is severely worn, which reduces production efficiency and leads to waste of resources)

Solution: serrated middle plate is adopted to evenly distribute airflow; The impeller adopts wear-resistant composite plate (wear-resistant layer is 6mm thick) with hardness HRC ≥ 62. The wear-resistant composite plate is added at the key position of the casing to improve the wear resistance of the casing and reduce the impact on the operating efficiency.

Transformation effect: the wear resistance of the fan is increased, and the number of maintenance is reduced.

Problem three: the original fan can not meet the noise requirements of the standard(At 48HZ, the noise exceeds the highest line 85dB)

Solution: Choose a silent aerodynamic model to fundamentally solve the noise problem; reduce the inlet and outlet airflow speed, reduce the noise generated by the impact of high-speed airflow; strictly control the gap between the collector and the impeller, and reduce the vortex at the air inlet of the fan.

Transformation results: the noise value of the fixed end bearing of the fan is 81.6dB, which meets the contract requirement of less than 85dB.

Problem four: the original fan vibration

Solution: The design conforms to aerodynamics, and at the same time ensures the accurate installation of the worm tongue to make the airflow inside the fan stable; SKF bearings are selected to ensure the long-term safe and stable operation of the fan; The supporting foot is designed to be thickened, and the welding height is as close to the center of the shaft as possible.

Transformation effect: the horizontal and vertical vibration values of the front and rear bearings are not more than 0.4 mm/s.

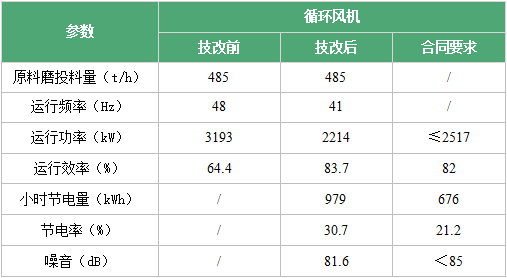

Comparison of parameters before and after technological transformation

After the transformation, the circulating fan runs stably with an operating efficiency of 83.7. The hourly power saving can reach 979kWh, with a power saving rate of 30.7. The noise value of the fixed end bearing of the fan is 81.6dB, which achieves the effect of noise reduction and vibration reduction. The speed margin increased from 48Hz to 41Hz under the same output, laying the foundation for later production.

The fan was successfully delivered in November 2019, the site operation is stable, all indicators are up to the requirements, has been recognized by the leaders of Huaying mud cement at all levels.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us