Efficient and reliable process technology to improve the quality of the motor

Release time:

2024-06-20

Selecting the appropriate annealing treatment process can eliminate the punching shear stress and restore the performance of cold-rolled silicon steel sheet.

The method of directly punching out the air gap has a significant effect on reducing stray losses.

Selecting the appropriate annealing treatment process can eliminate the punching shear stress and restore the performance of cold-rolled silicon steel sheet.

The end cover bearing chamber rolling process is adopted to improve its basic size, cylindricity and roughness accuracy, and reduce mechanical consumption, noise and bearing operating temperature.

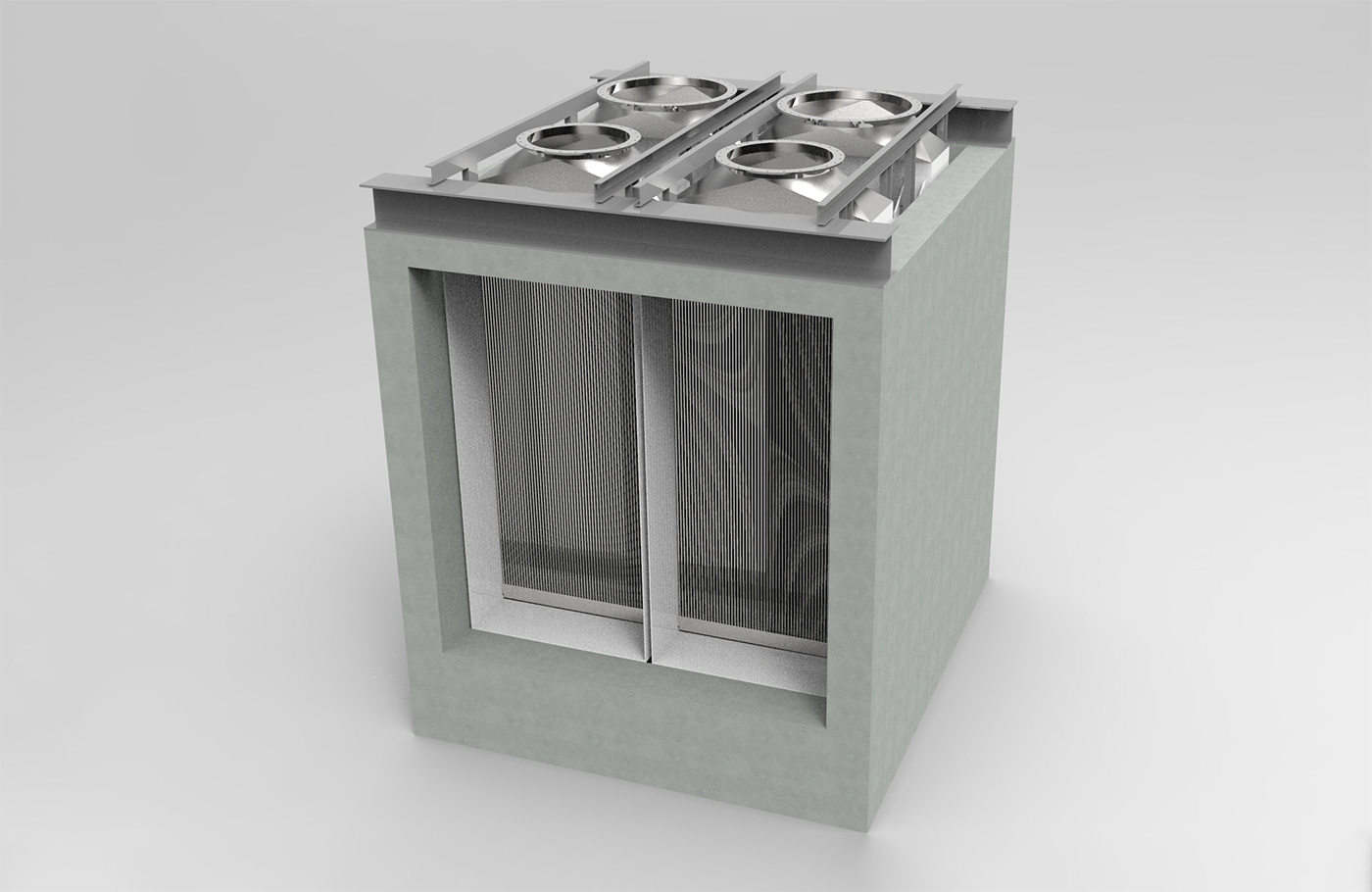

The oxidation process is used in the manufacture of stator and rotor punches. The punching sheet is placed in an oxidation furnace, heated to 550~580 ℃, the oxidant is introduced, and after the oxidation treatment under the specified conditions, a layer of uniform and firm film with good insulation properties is generated on the surface of the punching sheet. Excellent high temperature performance, and no insulation paint consumption, but also reduce the iron loss.

Previous Page

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us