Fan Energy Saving Technical Transformation Project of China United Cement Co., Ltd.

Release time:

2022-04-07

The enterprise has a domestic leading level of 5000t/d new dry cement production line, with an annual production of 1.8 million tons of high-quality clinker and 2.6 million tons of cement. This time is aimed at the energy-saving renovation of the original high temperature, circulating and tail exhaust fans. The operating efficiency of the original fans is 65.7, 63.8 and 59.1 respectively. After the renovation by our company, the operating efficiency of the fans has reached 81.6, 83.0 and 84.2 respectively. Under the same working conditions, the hourly power saving of the high temperature, circulating and tail exhaust fans has reached 1683kW (far exceeding the agreed value of 1157kW), it has been unanimously recognized by the top and leaders of Anyang Zhonglian.

China United Cement Group Co., Ltd. was established in 1999. It is the core enterprise of a large-scale central enterprise (China Building Materials Group Co., Ltd.) managed by the State-owned Assets Supervision and Administration Commission of the State Council. It has 101 wholly-owned and holding large-scale manufacturing enterprises. There are 27000 employees, with an annual production capacity of 0.11 billion tons of cement and 0.2 billion cubic meters of commercial concrete.

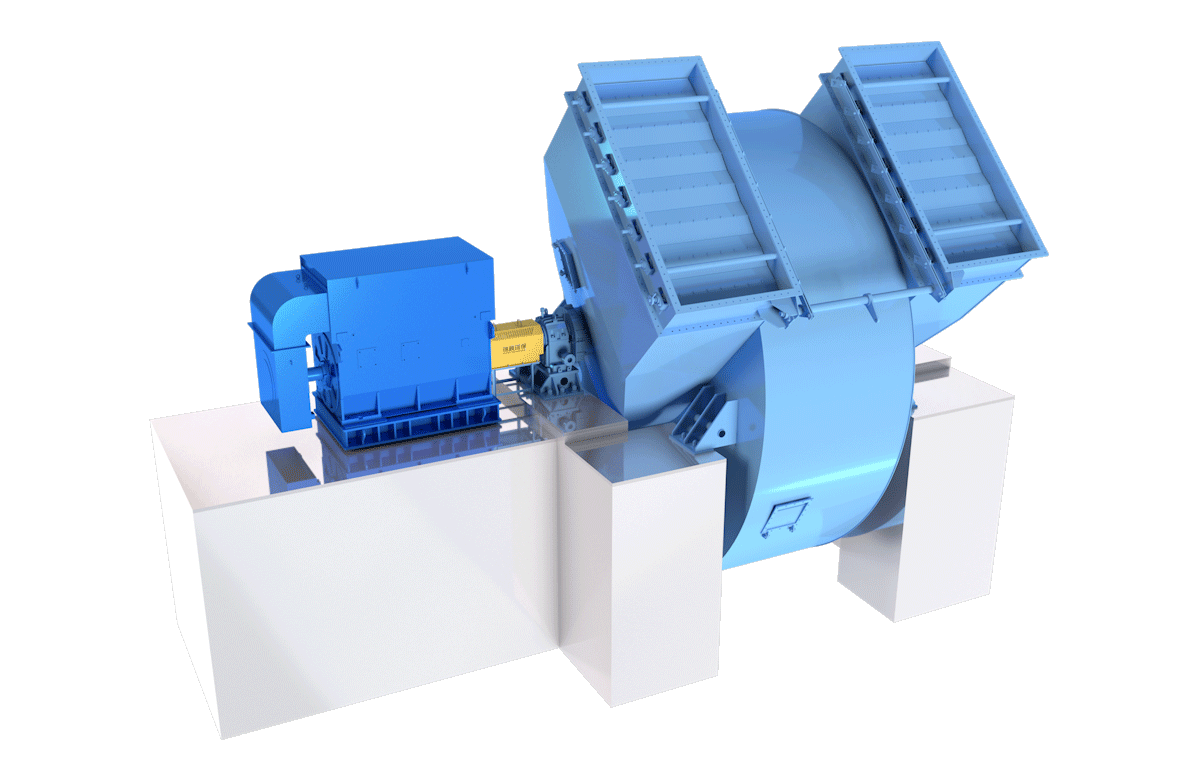

Anyang Zhonglian Cement Co., Ltd. high temperature, circulation, kiln tail fan transformation project

The enterprise has a domestic leading level of 5000t/d new dry cement production line, with an annual production of 1.8 million tons of high-quality clinker and 2.6 million tons of cement. This time is aimed at the energy-saving renovation of the original high temperature, circulating and tail exhaust fans. The operating efficiency of the original fans is 65.7, 63.8 and 59.1 respectively. After the renovation by our company, the operating efficiency of the fans has reached 81.6, 83.0 and 84.2 respectively. Under the same working conditions, the hourly power saving of the high temperature, circulating and tail exhaust fans has reached 1683kW (far exceeding the agreed value of 1157kW), it has been unanimously recognized by the top and leaders of Anyang Zhonglian.

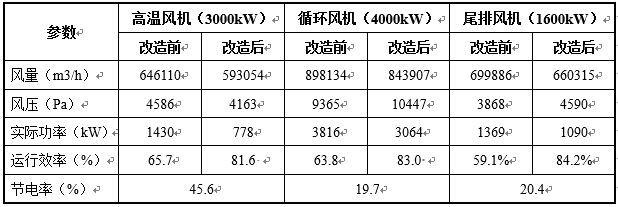

Comparison of parameters before and after technological transformation

Anyang Zhonglian Haihuang Cement Co., Ltd. High Temperature Fan Renovation Project

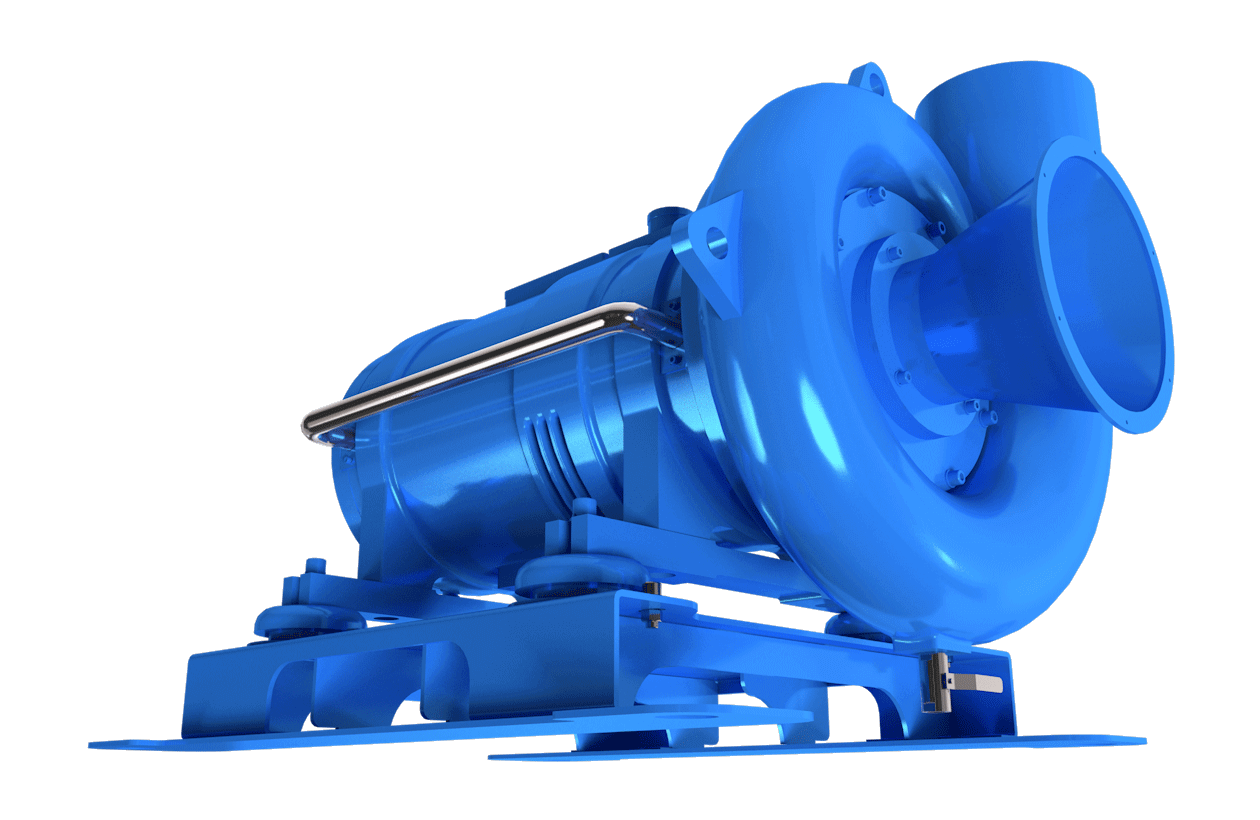

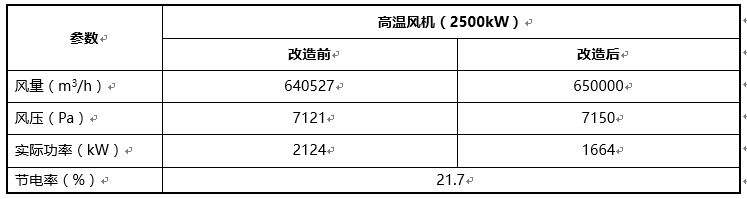

With the increasingly fierce competition in the cement industry, in order to reduce production costs, Zhonglian Cement Henan Regional Company and Shanghai Rychen in-depth cooperation to carry out energy-saving technological transformation of the five major fans of the clinker line, and selected Anyang Zhonglian Haihuang 4500T/D clinker line high-temperature fan as a pilot.

The installation of the high-temperature fan was completed in July 2016. After nearly a month of trial operation, the equipment has been operating stably, and the power saving rate has reached 21.7. It has been recognized by Zooming Cement Henan Regional Company and will cooperate in many branches.

Comparison of parameters before and after technological transformation

In 2018, our company modified the kiln head fan of 4500T/D line. After the transformation, the equipment is stable in operation, the fan operation efficiency is increased from 63.7 to 83.1, and the hourly power saving reaches 169kWh, which is unanimously recognized by the senior management and leadership of Anyang Zhonglian Haihuang.

Comparison of parameters before and after technological transformation

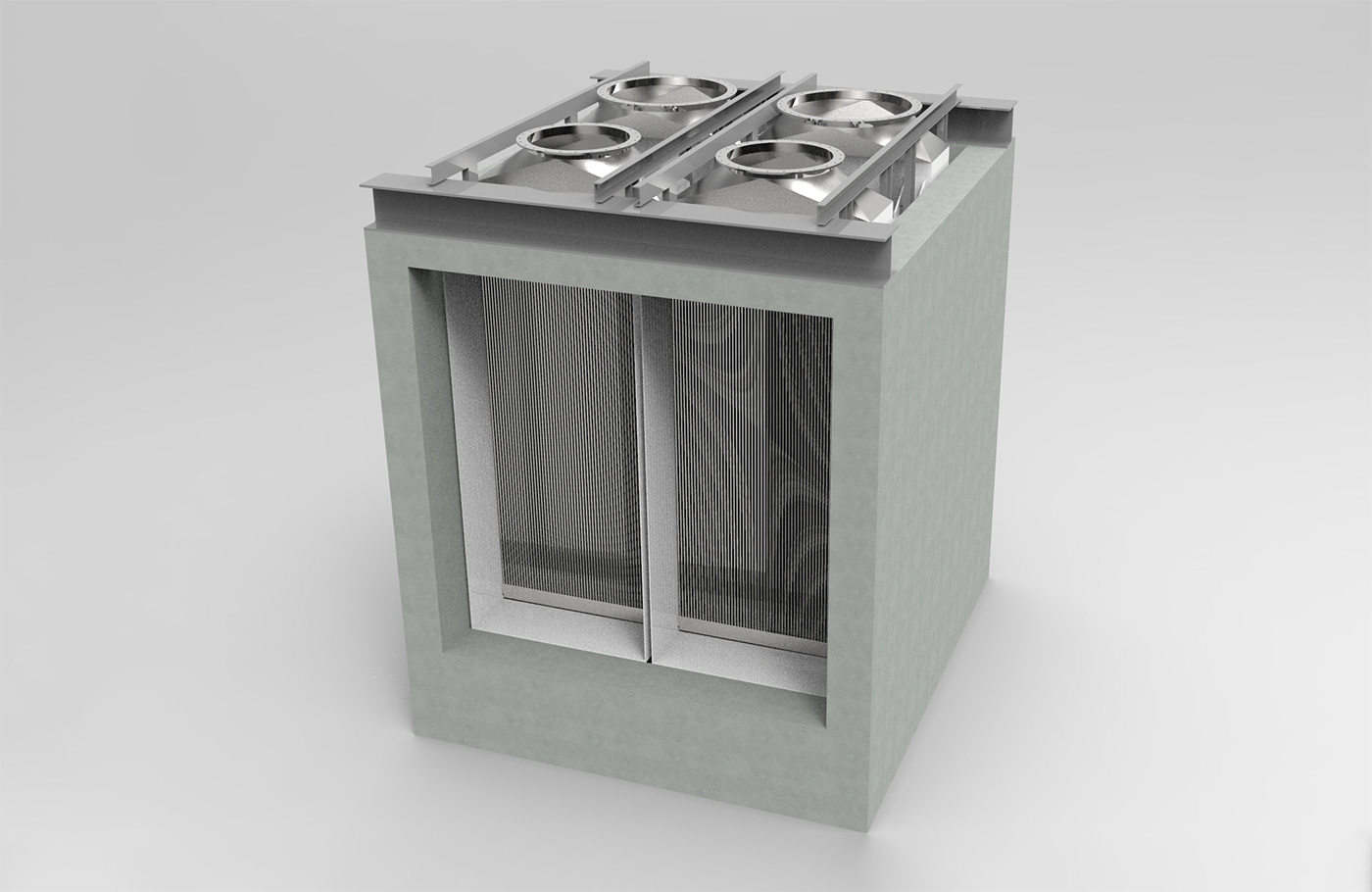

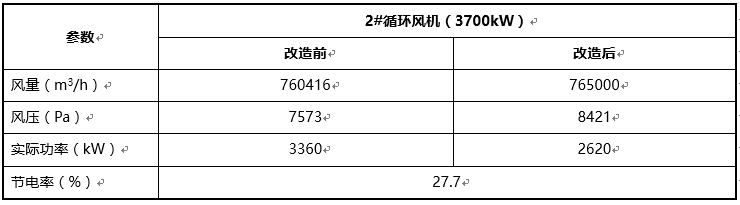

Energy Saving Technical Transformation Project of 2# Circulating Fan of Xin 'an Zhonglian Wanji Cement Co., Ltd.

Xin'an Zhonglian Wanji Cement Co., Ltd. is a cement clinker production enterprise jointly held by China United Cement Group Co., Ltd. and Wanji Holding Group Co., Ltd. Two cement clinker production lines will be constructed in two phases, which is located in the industrial agglomeration area of Xin'an County, Henan Province. With an annual output of 3 million tons of cement, the scale of production occupies the forefront in western Henan.

Xin'an Zhonglian Wanji Cement in-depth implementation of the supply-side reform policy, improve the competitiveness of enterprises, selected 2 raw material mill cycle fan as a pilot. Shanghai Rychen received technical approval from Xin'an Zhonglian through many on-site surveys and many exchanges with Xin'an Zhonglian on the renovation plan. The two parties signed a renovation agreement in May 2017 and completed the renovation and delivered it to use in July. The operation of the equipment is stable. Under the premise of a substantial increase in wind pressure, there is still a power saving of 740 degrees per hour, which has been unanimously recognized by the user and senior leaders.

Comparison of parameters before and after technological transformation

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us