Jiangsu Shagang Group Huaigang Special Steel Co., Ltd. Fan Energy Saving Technical Transformation Project

Release time:

2022-04-07

At the beginning of 2016, the 2# coke oven of Huaigang was overhauled. In order to meet the environmental protection requirements, the dust removal fan needs to be modified. According to the calculation of the design institute, the air volume has increased from 190000 m3/h to 260000 m3/h, and the motor has changed from 560kW to 710kW. Therefore, it is necessary to purchase fans, motors, frequency converters, etc. again, and to rebuild the civil foundation, which takes at least 7 days, affecting production. However, our company only needs to customize a "Rui Chang" high-efficiency and energy-saving fan to meet the needs.

Jiangsu Shagang Group Huaigang Special Steel Co., Ltd. has total assets of 8 billion yuan and 5800 employees, including 3000 professional and technical personnel. The company has an annual output of 3 million tons of special steel and materials such as spring steel, bearing steel, marine anchor chain steel, alloy pipe blank steel and automobile steel. The products are mostly used in automobile, railway, petroleum, marine, mining, coal, energy, machinery manufacturing and other industries.

Coking plant coke oven dust removal fan transformation project (pilot)

At the beginning of 2016, the 2# coke oven of Huaigang was overhauled. In order to meet the environmental protection requirements, the dust removal fan needs to be modified. According to the calculation of the design institute, the air volume has increased from 190000 m3/h to 260000 m3/h, and the motor has changed from 560kW to 710kW. Therefore, it is necessary to purchase fans, motors, frequency converters, etc. again, and to rebuild the civil foundation, which takes at least 7 days, affecting production. However, our company only needs to customize a "Rui Chang" high-efficiency and energy-saving fan to meet the needs.

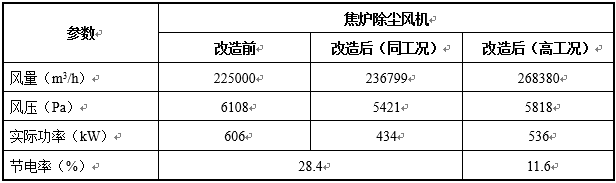

In the end, Huaigang decided to take the project as a pilot project and implement it by our company. In July 2016, the project took only 20 hours to complete the installation and acceptance as scheduled, effectively reducing economic losses. The power saving rate is as high as 28.4 under the working conditions before technological transformation. Under the working conditions of increasing air volume to meet the environmental protection requirements, the power saving rate is still 11.6, which has been unanimously approved by the users and senior management of Huaigang.

technical reform before and after the comparison of parameters:

Fan Renovation Project of Sintering and Ironmaking Plant

In view of the perfect delivery of the pilot project, at the end of 2016, Huaigang invited our company to conduct a comprehensive evaluation of the fans in its ironmaking plant and sintering plant. After detailed investigation and field testing, 11 fans were selected for energy-saving technological transformation. At the end of 2017, Shanghai Ruichen completed the transformation of 11 fans, with an average power saving rate of 34.9 percent and a remarkable energy saving effect. Among them, the sintering main exhaust fan can save 1886kWh per hour.

technical reform before and after the comparison of parameters:

Electric furnace discharge dust removal fan renovation project

After investigation and testing, it is found that the operation efficiency of the dust removal fan outside the electric furnace is low, less than 35%, and the existing air volume cannot meet the needs of production improvement. Shanghai Ruichen adopted "high-efficiency fluid conveying technology" to carry out energy-saving transformation on the fan. After the transformation, the operation efficiency of the fan is as high as 81.2. On the basis of greatly increasing the air volume and air pressure, it can also save 133kWh of electricity per hour, which is highly recognized by customers.

technical reform before and after the comparison of parameters:

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us