Comprehensive Solution for High Efficiency Motor

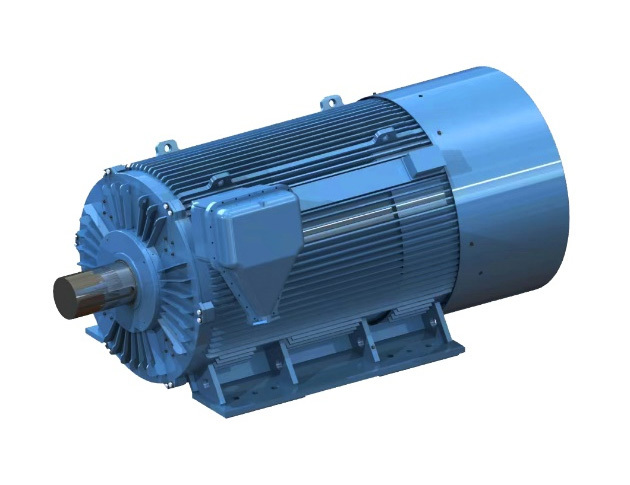

1. High efficiency rare earth permanent magnet synchronous motor

Product Description and Usage

The extremely high-efficiency permanent magnet synchronous motor can directly replace the original asynchronous motor, its size, specification and installation method are the same as the original asynchronous motor, especially if the load rate is not high or the working conditions need to be changed. Permanent magnet synchronous motors have been widely used due to their advantages such as high efficiency, high power factor, strong load starting ability, low noise, low temperature rise, and longer service life compared to asynchronous motors.

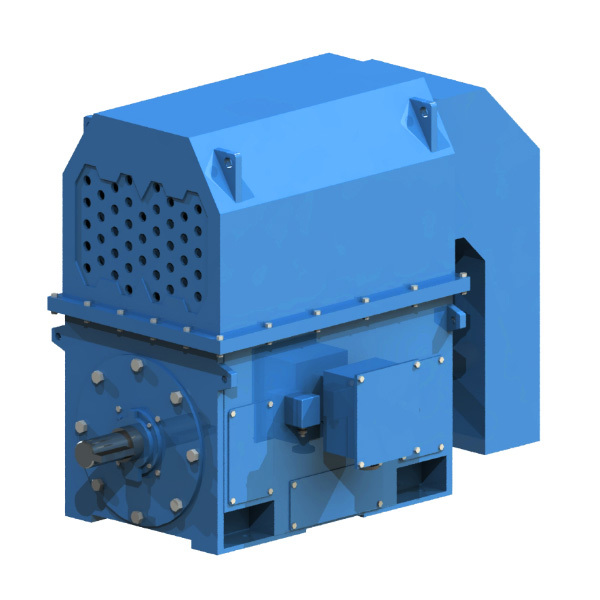

2. Low speed high torque permanent magnet direct drive motor

Product Description and Usage

Direct drive refers to the direct connection between the motor and the load device, eliminating the multi-level connectors, gearbox, and related oil pump stations in traditional drive units. The direct drive system has the characteristics of simple structure, stability, high efficiency, environmental protection, and energy conservation. It is widely used in industries such as cement, steel, electricity, ports, petrochemicals, food and oil, biopharmaceuticals, papermaking, and mining.

Advantage Features

High efficiency and energy saving

The entire product line meets the national standard for first level energy efficiency, using permanent magnet materials to provide the rotor magnetic field, resulting in high motor efficiency and high power factor.

Simple structure and reliable operation

Permanent magnet motors use rare earth elements, and permanent magnet materials replace the excitation winding of asynchronous motors, making the structure simpler and more reliable.

Good dynamic performance

The permanent magnet motor has a small rotor inertia, allows for a large pulse torque, can achieve high acceleration and practical speed, and has good dynamic performance.

Strong adaptability to environment and working conditions

It has strong load starting and overload capacity, with adjustable frequency and speed suitable for different working conditions. The soft starter that regulates pressure has little impact on the power grid.

Maintenance-free

Permanent magnet motors have no rotor windings, carbon brushes, or slip rings, significantly reducing maintenance costs in the later stages.

Small impact on the surrounding environment

Due to its compact and simple structure, maintenance free, and fully enclosed design, it is more suitable for working in harsh environments with high humidity or dust or precision requirements.

Related Cases

Wengyuan Zhongyuan Development Co., Ltd.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us