Permanent Magnet Direct Drive Solution

Integrated solution for permanent magnet direct drive

The energy efficiency level of permanent magnet direct drive motors is Level 1, which can greatly improve transmission efficiency and reliability;

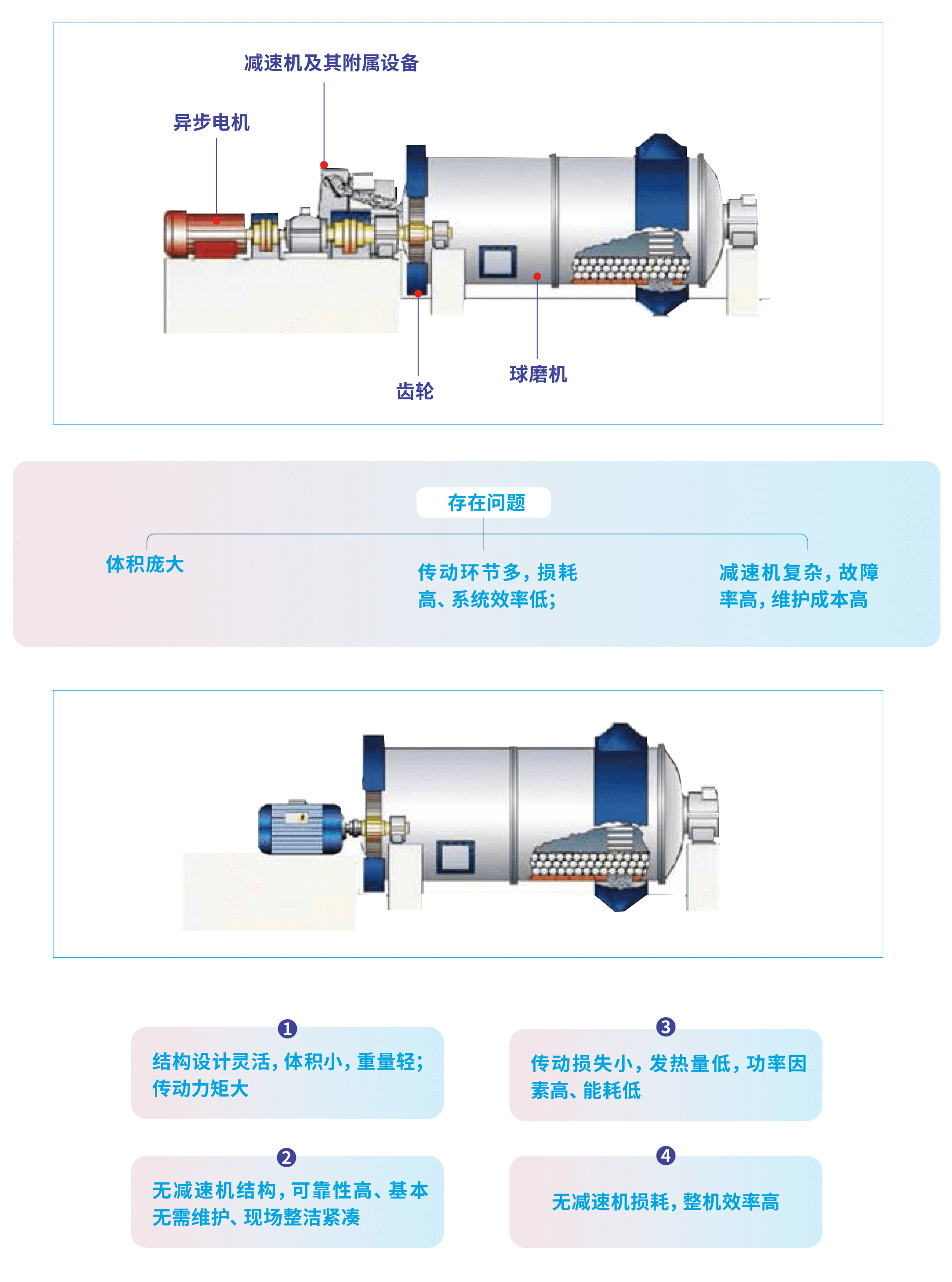

Ball Mill

The ball mill is a rotating device with a horizontal cylindrical appearance. It is driven by gears, sprockets or belts on the outer edge. When the ball mill cylinder starts to rotate, the materials are loaded into the cylinder by the hollow shaft at the feeding end of the ball mill. The combined action of inertia, centrifugal force and friction force realizes material parabolic operation and completes grinding.

Cooling tower

Cooling tower is a device that uses water as a circulating coolant to absorb heat from a system and discharge it to the atmosphere to reduce the water temperature. It is an evaporative heat dissipation device that uses water and air flow to exchange heat and produce steam. The steam evaporates and carries away heat to achieve evaporative heat dissipation, convective heat transfer, and radiative heat transfer to dissipate the waste heat generated in industry or refrigeration and air conditioning, thereby reducing the water temperature and ensuring the normal operation of the system. The device is generally barrel-shaped.

Hoist

A hoist is a continuous conveying machinery that uses a series of hoppers uniformly enclosed on an endless traction component to vertically lift materials. Its working principle is that the hopper lifts the materials from the lower bin, and as the conveyor belt or chain lifts them to the top, they flip down around the top wheel, and the hopper tilts the materials into the receiving groove.

Belt conveyor

Belt conveyors have fixed and mobile types, with a simple structure and high efficiency. They are continuous conveying machinery that use flexible conveyor belts as material carrying and traction components. Its working principle is that an endless conveyor belt surrounds the driving roller and the reversing roller, and the upper and lower branches between the two rollers are supported by several pallets. The material is placed on the upper branch, and the friction between the driving roller and the belt is used to pull the conveyor belt and the material to run.

Powder selecting machine

Powder selection machines are generally divided into three types: cyclone, triple separation, and centrifugal. Their working principle is to separate, screen, and collect fly ash that meets the accuracy requirements through the action of airflow after production. They are widely used in coal mill, raw material mill, and cement mill systems of the new dry cement production line.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us