Product Development

Magnetic levitation blower

Working principle

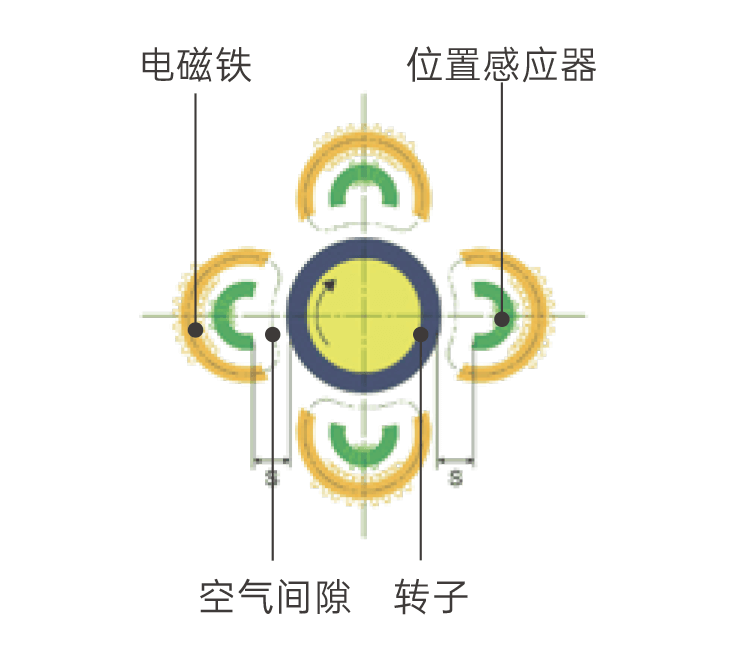

The magnetic levitation high-speed centrifugal fan adopts a direct drive structure of high-speed permanent magnet synchronous motor, which integrates centrifugal impeller and motor drive. Through the built-in displacement sensor, the displacement state of the rotating shaft is detected in real time. The collected signal is sent to the magnetic bearing controller for modulation and calculation, and the control current is generated. Then the current is input into the magnetic bearing coil to generate electromagnetic force, so as to adjust the suspension of the rotating shaft.

Core Components

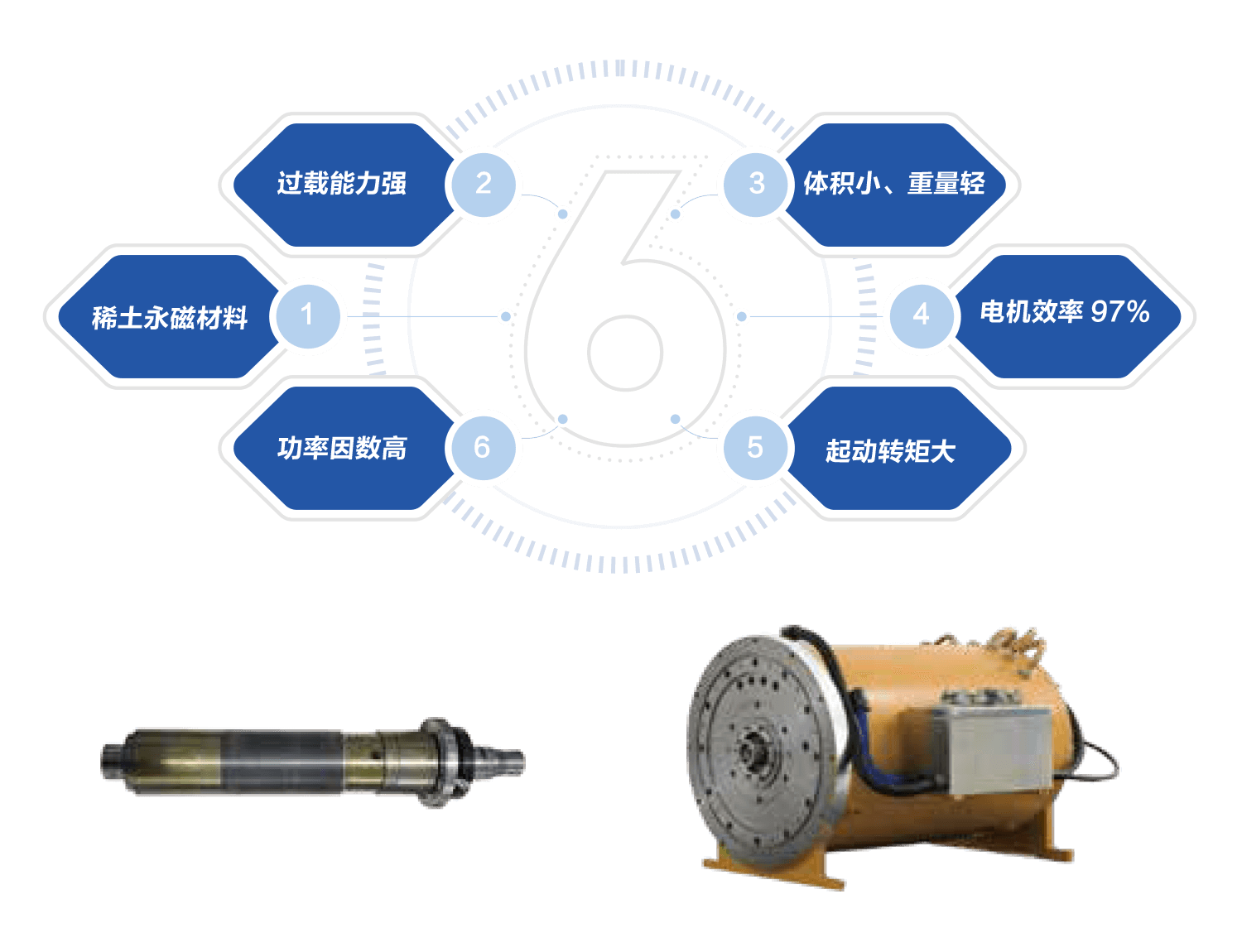

High-efficiency high-speed permanent magnet motor

Highly reliable magnetic bearings

Magnetic suspension control technology is the core technology of magnetic suspension bearing. It uses high-precision digital controller, high-precision PID control and unbalanced compensation algorithm, and adopts redundant design of power-off safety protection mode to realize stable high-speed suspension of shaft.

● Linkage control, automatic protection

Linked with the protection of the frequency converter, it decelerates and stops at the moment of power outage to ensure the protection of the bearings.

● Uninterruptible power supply protection

The use of imported brand protection power supply can provide secondary power supply for magnetic bearings within 4ms of accidental power failure to ensure the power-off operation of magnetic bearings.

● Auxiliary machinery bearing protection

The auxiliary mechanical bearings adopt imported customized products, which have been verified through more than ten instantaneous drop tests to ensure the safety of the motor rotor and magnetic bearings, and can be easily replaced.

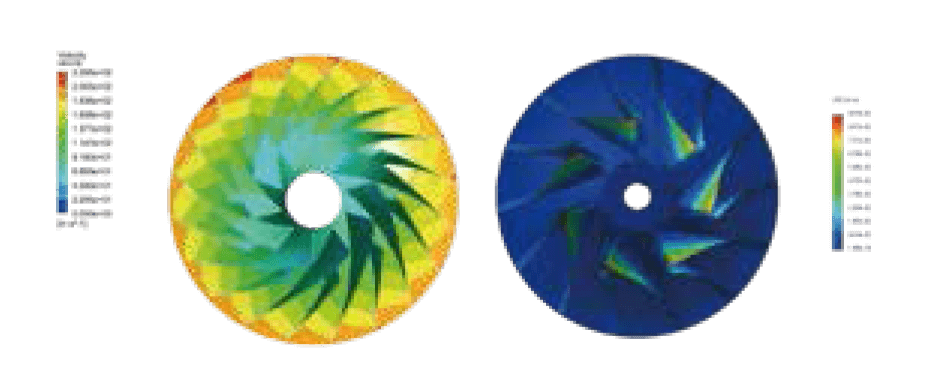

Efficient pneumatic model

● Direct drive has high reliability and no transmission loss.

● The impeller is made of high-strength aviation aluminum AL7075.

● Five-axis linkage machining of impeller has higher dimensional accuracy.

● Tailor-made design of impeller.

● Ensure that the fan model efficiency of each project is above 80%.

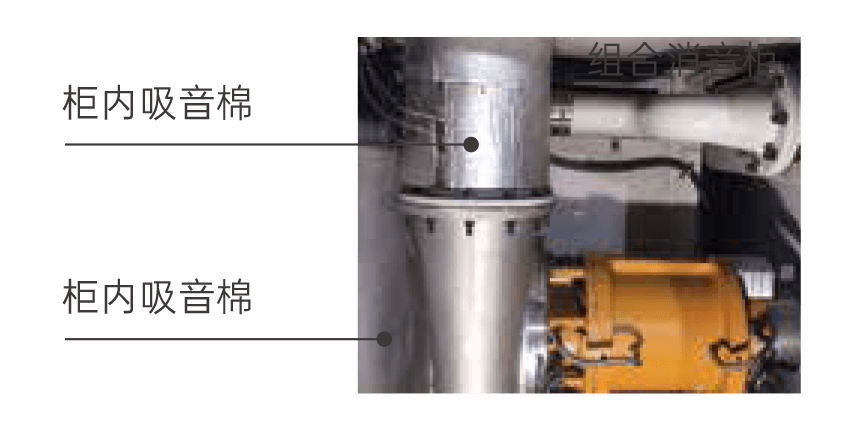

Low noise combination design

● The combination of the imported silencer filter and the sound-absorbing cotton in the cabinet reduces the noise level to below 80dB.

Intelligent control

The intelligent human-machine interaction system, which adapts to the remote and local control methods of user process requirements, realizes the most convenient operation of the fan. All data indicators are clear at a glance through the display, and remote data transmission can be achieved through Ethernet or DP.

● Three modes of regulation

1. Speed mode

2. Pressure mode

3. Flow pattern

● Simple operation, stronger process

● Real-time visual viewing

● Fan operating condition data

● Alarm prompt

● Remote monitoring

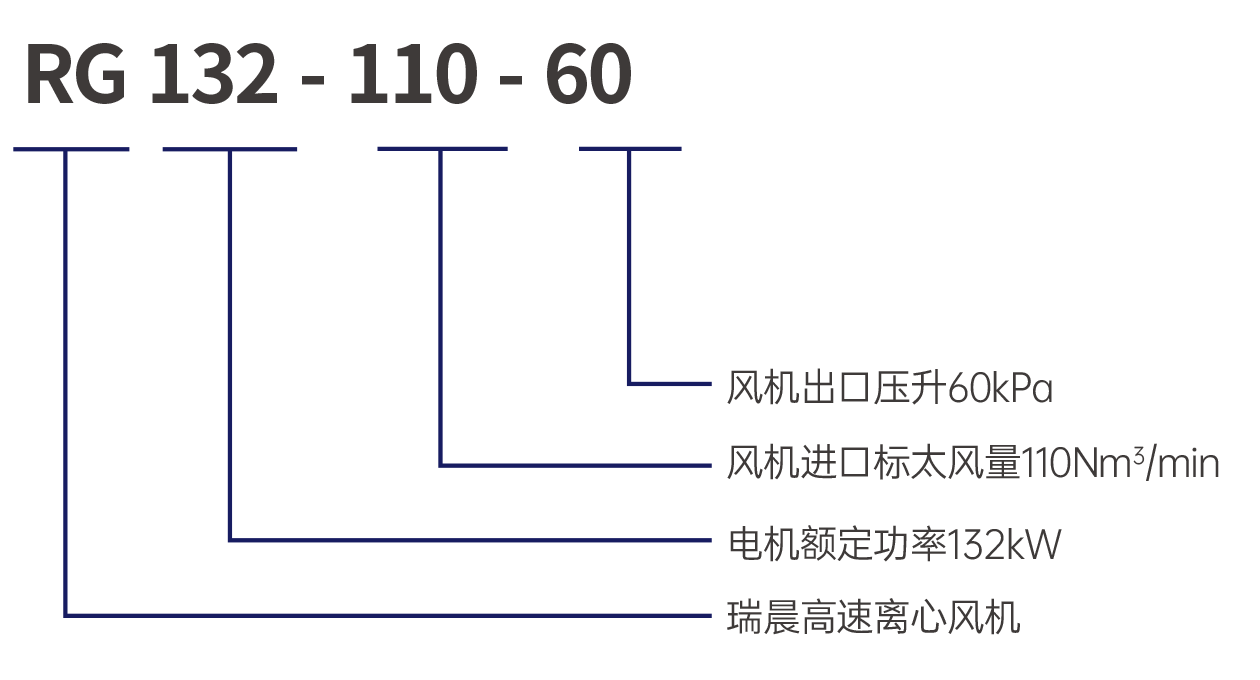

Product Model

Related Products

The magnetic levitation high-speed centrifugal fan adopts a direct drive structure of high-speed permanent magnet synchronous motor, which integrates centrifugal impeller and motor drive. Through the built-in displacement sensor, the displacement state of the rotating shaft is detected in real time. The collected signal is sent to the magnetic bearing controller for modulation and calculation, and the control current is generated. Then the current is input into the magnetic bearing coil to generate electromagnetic force, so as to adjust the suspension of the rotating shaft.

View moreGas blower is mainly used for gas transmission, pressurization and other purposes. It is widely used in blast furnace gas, coke oven gas, converter gas and so on. The structural form of the gas blower is a single-stage cantilever, and the bearings include sliding bearings, rolling bearings, etc.

View moreContact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us