Product Development

CDQ circulating fan

As the power central device of the CDQ system, the CDQ circulating fan plays a vital role. However, in both imported and domestic processes, the CDQ circulating fan is operated by a single machine without a spare fan, so the requirement for the stability of the fan is extremely high. Moreover, due to the high dust content, high hardness and high operating speed of the coke powder in the circulating gas, the requirement for the wear resistance of the fan is extremely high. Therefore, domestic CDQ circulating used to be imported products before, mainly supplied by German TLT and other foreign brands.

At present, a large number of imported products are used in domestic CDQ circulating fans, and the technical level of the existing domestic CDQ circulating fans is relatively backward. Rychen has carried out domestic research and development for this fan, replacing imported fans with high-performance domestic fans, reducing equipment procurement costs and maintenance costs, and improving the technical level and international competitiveness of China's equipment manufacturing industry. At present, 140T series and 190T series have been successfully put into operation in the steel industry.

Technical features

1. High operational efficiency

On the basis of digesting foreign advanced pneumatic models, our company has developed a new generation of high-efficiency centrifugal fans for steel plant fans and new dry cement production processes. The operating efficiency of the CDQ circulating fan can reach 83.5%, and the fan efficiency curve has a wide range of high efficiency, which can still be maintained within the high efficiency range under the condition of working condition adjustment;

[The efficiency of Shanghai Rychen's high-efficiency and energy-saving fan exceeds the level 1 energy efficiency value specified in the national standard GB19761-2020 "Fan Energy Efficiency Limit Value and Energy Efficiency Grade.]

2. Stable operation of equipment

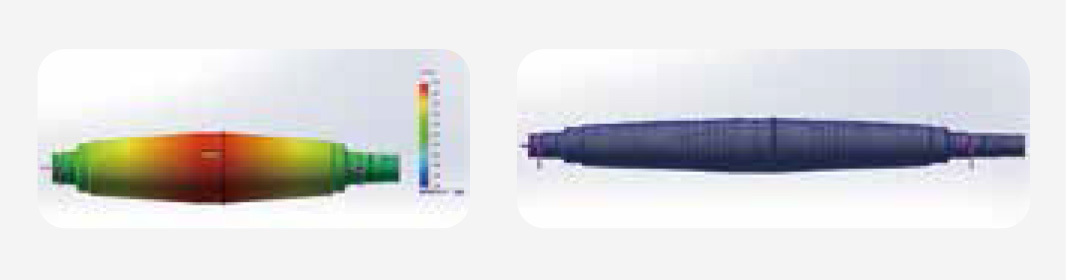

a. High spindle safety: The main shaft is made of 35CrMo or higher performance materials, and the first-order critical safety margin is ≥ 1.45, which is much higher than the national multiple of (1.25~1.30), making the fan main shaft more rigid and improving the operation stability;

B. High air tightness: The shaft seal is sealed with nitrogen barrier carbon ring to effectively prevent leakage at the shaft seal; the casing is sealed with finishing double-layer PTFE to ensure the air tightness of the casing joint. After the production and processing is completed, the air tightness of the casing shall be inspected by means of air tightness test;

c. The bearing adopts sliding bearings, and the cooling method is forced lubrication of the thin oil station. At the same time, self-lubricating air cooling can also be realized to prevent the extreme situation that the thin oil station cannot supply oil;

d. The rotor dynamic balance level is G2.5, reducing the unbalance to the lowest level;

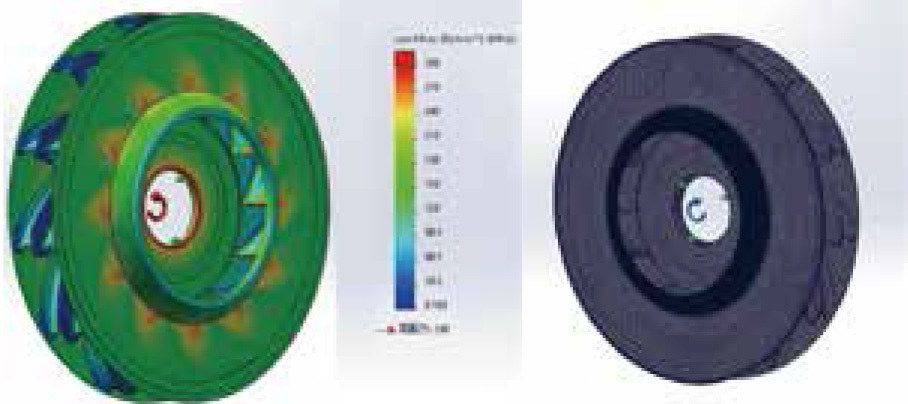

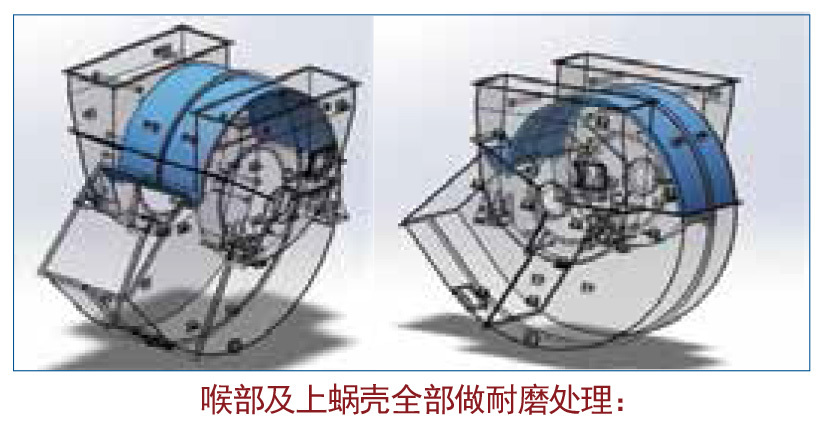

3. High wear resistance of fan

The wear-resistant composite plate is used for the wear-resistant area of the impeller, the wear-resistant part of the volute and the upper shell of the casing. The surface hardness of the wear-resistant layer is greater than 59 ~ 62HRC, and the hard phase content is greater than 50%. The wear-resistant material adopts the imported brand "Castelin" high-strength wear-resistant lining plate. The wear-resistant layer is flat and high in hardness, which can greatly reduce the aerodynamic loss caused by the fan blade wear and gas flow, reduced maintenance costs.

Welds at the junction of the blade at the blade outlet and the front disk and the middle disk are surfacing with wear-resistant electrodes (the welding height is not less than the thickness of the blade) to improve the quality of the welds and resist airflow erosion;

4. Short construction period

The design of the scheme drawings is all carried out on the Solidworks software, and efforts are made to restore the fan foundation and the surrounding original environment. At the same time, the fan transformation is combined with the existing conditions to ensure the use of the existing foundation, so as to maximize efficiency, minimize on-site construction and simplify maintenance.

5. Domestic design, procurement, and processing

Rychen has built a complete production line and R & D base in Huzhou, Zhejiang Province. All components are designed and produced by Rychen. Carbon ring seals, sliding bearings and couplings are all matched by domestic big-name manufacturers, and the products are safe and reliable.

Related Products

As the power central device of the CDQ system, the CDQ circulating fan plays a vital role. However, in both imported and domestic processes, the CDQ circulating fan is operated by a single machine without a spare fan, so the requirement for the stability of the fan is extremely high. Moreover, due to the high dust content, high hardness and high operating speed of the coke powder in the circulating gas, the requirement for the wear resistance of the fan is extremely high. Therefore, domestic CDQ circulating used to be imported products before, mainly supplied by German TLT and other foreign brands.

View moreA combustion fan is a device used to increase the oxygen concentration during combustion. Its working principle is to inhale air through a fan, and a specially designed combustion aid device increases the oxygen concentration in the air. Then, the increased air concentration is injected into the burner and mixed with fuel for combustion, thereby improving combustion efficiency and reducing fuel consumption. In the industrial field, combustion fans are usually used in burners, furnaces and other equipment, which can increase the combustion efficiency of gas, oil and solid fuels by 20% to 30%, thereby significantly reducing environmental pollution and energy consumption.

View moreContact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us