Axial Air Staged Combustion Technology

Release time:

2022-02-21

At present, synthesis gas will become one of the widely used energy sources in the future. Among them, synthesis gas with high hydrogen content is easy to cause backfire of burners due to the very high combustion speed of flame surface [1,2]. Therefore, most of these burners generally adopt the form of diffusion combustion, which makes the nitrogen oxide emission of burners with this kind of fuel higher. In order to meet the environmental requirements, it is necessary to develop a new combustion organization technology. Rich-Rapid Mixing-Lean Burn (RQL) is a technology developed to address the flashback problem and the nitrogen oxide emission problem.

At present, syngas will become one of the widely used energy sources in the future, in which syngas with high hydrogen content is likely to cause backfire of the burner due to the very high combustion speed of the flame surface.[1,2]Therefore, most of these burners generally use the form of diffusion combustion, which makes the nitrogen oxide emissions of the burner higher. In order to meet the environmental requirements, it is necessary to develop a new combustion organization technology. Rich-Rapid Mixing-Lean Burn (RQL) is a technology developed to address the flashback problem and the nitrogen oxide emission problem.

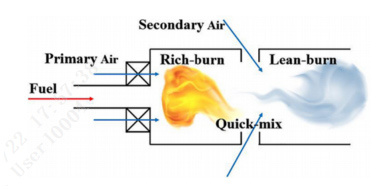

Fig. 1 Schematic diagram of RQL burner

Fig. 1 Schematic diagram of an RQL combustor

Figure 1 is a schematic diagram of the RQL combustion chamber, which mainly contains three zones: a fuel-rich zone, a fast mixing zone and a fuel-lean zone. All fuel is injected into the rich combustion zone, and the air is divided into two parts, which are injected into the rapid mixing zone and the lean combustion zone respectively. In the first stage combustion region, the fuel is excessive, and the reducing atmosphere is maintained to suppress NOx generation. After the second-stage combustion area is injected with air, the air is excessive and the fuel is burned out[3]. The tissue combustion mode can avoid the chemical equivalent flame. RQL tissue combustion method has been successfully applied to the aero-engine combustion chamber[4-7].

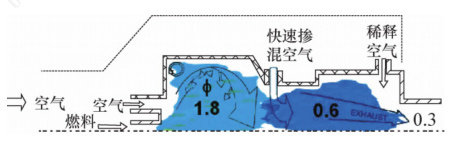

Fig. 2 Schematic Diagram of RQL Combustion Chamber of GE Company

Fig. 2 GE schematic diagram of an RQL combustor

RQL combustors have not been widely used in gas turbines. GE conducted a full-scale RQL combustor test and the results did reduce NOx emissions. Related studies have shown that when the gas temperature is lower than 1600 ℃, the air distribution equivalence ratio of rich and lean stages is the key to affect NOx. The difficulty of this technique is that rapid blending is difficult to achieve, and the NOx emissions of axial air staging are slightly worse than axial fuel staging. However, due to the rich combustion zone at the head, it is especially suitable for small load conditions, stable combustion, and no backfire. Therefore, in the selection of combustion organization technology should be comprehensive consideration.

References:

[1] Hui, X., Zhang, Z., Mu, K., Wang, Y., and Xiao, Y., 2007, “Effect of Fuel Dilution on the Structure and Pollutant Emission of Syngas Diffusion Flames,” ASME Paper No. GT2007-27481.

[2] Shi, B., Li, B., Zhao, X., Chen, R., Fujita, O., and Wang, N., 2018, “Rapidly Mixed Combustion of Hydrogen/Oxygen Diluted by N2 and CO2 in a Tubular Flame Combustor,” Int. J. Hydrogen Energy, 43(31), pp.14806–14815

[3] Li Suhui, Zhang Guihua, Wu Yuxin. Review of advanced combustion technology for future gas turbine [J]. Journal of Tsinghua University (Natural Science Edition),2021,61(12):1423-1437.DOI:10.16511/j.cn ki.qhdxxb. 2022.25.001.

[4] McKinney, R., Cheung, A., Sowa, W., and Sepulveda, D., 2007, “The Pratt &Whitney TALON X Low Emissions Combustor: Revolutionary Results With Evolutionary Technology,” AIAA Paper No. 2007-386.

[5] Ingenito, A., Agresta, A., Andriani, R., and Gamma, F., 2014, “RQL Combustion as an Effective Strategy to NOx Reduction in Gas Turbine Engines,”ASME Paper No. IMECE2014-36898.

[6] Kyprianidis, K. G., Nalianda, D., and Dahlquist, E., 2015, “A NOx Emissions Correlation for Modern RQL Combustors,” Energy Procedia, 75, pp.2323–2330.

[7] Kyprianidis, K. G., and Dahlquist, E., 2017, “On the Trade-Off Between Aviation NOx and Energy Efficiency,” Appl. Energy, 185, pp. 1506–1516.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us