No. 1 Furnace Air Preheater Renovation Project of Meigang 1422 Line

Release time:

2022-02-21

Shanghai Meishan Iron and Steel Co., Ltd. Hot Rolling Plant 1422mm Hot Rolling Furnace No.1 was put into operation in November 1993, and completed the technical transformation of combustion and cooling system in 2009. The fuel of the furnace is high-coke mixed gas, and regular burners are used for heating and continuous combustion control. The heating furnace is a walking beam heating furnace, and the furnace type is a three-stage heating side-to-side walking beam heating furnace. The heating furnace is divided into preheating section, heating section, heating section and soaking section along the furnace length from the charging end to the discharging end. In order to fully and effectively recover the waste heat of flue gas, a tubular air preheater is set in the flue.

Basic information of heating furnace

Shanghai Meishan Iron and Steel Co., Ltd. Hot Rolling Plant 1422mm Hot Rolling Furnace No.1 was put into operation in November 1993, and completed the technical transformation of combustion and cooling system in 2009. The fuel of the furnace is high-coke mixed gas, and regular burners are used for heating and continuous combustion control. The heating furnace is a walking beam heating furnace, and the furnace type is a three-stage heating side-to-side walking beam heating furnace. The heating furnace is divided into preheating section, heating section, heating section and soaking section along the furnace length from the charging end to the discharging end. In order to fully and effectively recover the waste heat of flue gas, a tubular air preheater is set in the flue.

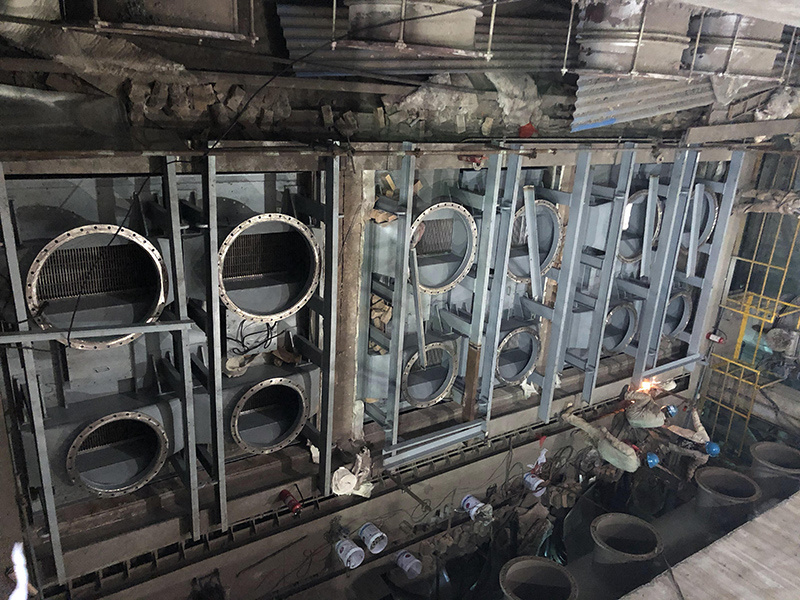

Application of tubular heat exchanger

The original air preheater is a traditional tube preheater, the heat exchange efficiency is low, and because of the tube form heat exchanger ash problem is serious so that the heat exchanger efficiency is reduced year by year, directly affect the thermal efficiency of the heating furnace and the safe operation of the heating furnace, improve the operating cost of enterprises and increase the security risks.

The technical parameters of the original tubular air preheater are shown in Table 1.

Table 1 Parameters of tubular air preheater

| Project |

RatedWorking condition |

Max.Working condition |

Unit |

| Total air volume |

72080 |

97520 |

Nm3/h |

| Total flue gas volume |

98600 |

133400 |

Nm3/h |

| Number of preheater sets |

6 |

6 |

Group |

| Air volume per group |

12013 |

16253 |

Nm3/h |

| Amount of smoke in each group |

16433 |

22233 |

Nm3/h |

| Air inlet temperature |

20 |

20 |

℃ |

| Flue gas inlet temperature |

620 |

620 |

℃ |

| Air outlet temperature |

360 |

330 |

℃ |

| Flue gas outlet temperature |

420 |

390 |

℃ |

| Heat exchange area of single group heat exchanger |

266.2 |

266.2 |

m2 |

| air resistance |

1616 |

2654 |

Pa |

| Smoke resistance |

58 |

110 |

Pa |

The main problems of flue gas waste heat recovery by tubular heat exchanger are as follows:

1) Low efficiency of flue gas waste heat recovery

The original air preheater is a traditional tube type, its heat exchange efficiency is low, and the material reason requires the flue gas inlet temperature to be limited to a lower level, the need to mix cold air to cool the flue gas, on the one hand, increase the cold air fan power consumption, on the other hand, the heat loss is large.

2) serious ash problem

The original air preheater is a tubular preheater, and the horizontal heat exchange tube in the flue gas flow direction blocks the flue gas flow, so the dust accumulation problem due to structural reasons cannot be solved. Moreover, the auxiliary dust removal device is not installed in the heat exchanger components. During the operation of the equipment, the heat exchange efficiency decays year by year, and the air waste heat temperature drops significantly after more than 6 months of operation.

3) Gas overtemperature alarm

In the actual production process, the air preheating temperature of No.1 heating furnace is relatively low, and the flue gas temperature of the air preheater is relatively high. Even if the dilution fan is turned on to mix cold air into the flue to cool the temperature, the gas preheating temperature of the subsequent gas preheater often reaches above 320 ℃, and an over-temperature alarm occurs (the gas over-temperature alarm temperature is 320 ℃). This not only increases the opening frequency of the dilution fan, increases the power consumption, but also can not make full use of the waste heat of the flue gas, but also has a greater safety operation hidden danger.

The basic characteristics of plate heat exchanger

Plate heat exchanger is a special enhanced heat transfer plate as the heat transfer surface, in the flue gas and air flow in the process of forming turbulence, thereby destroying the heat transfer surface boundary layer [9], effectively enhanced heat transfer.

The technical characteristics of the new high-efficiency plate heat exchanger are as follows:

1) the use of high temperature, the use of stainless steel material, the use of temperature can reach more than 1100 ℃;

2) The structure is compact, and the floor area is only about 1/3 of the tube heat exchanger, which is especially suitable for the limited space layout requirements of the walking beam heating furnace tunnel.

3) The heat transfer efficiency is nearly 1 times higher than that of the tube, while the pressure drop increase is not obvious. The metal consumption is low, and under the premise of the same heat load, the metal consumption is only about 1/3 of the tube type.

4) Since the plate surface of the plate air preheater is close to the mirror surface and is consistent with the flow direction of the flue gas, it is not easy to accumulate ash, and even a small amount of ash can be removed by cleaning or ultrasonic soot blowing.

5) Since the plate air preheater is made of stainless steel, the service life is greatly extended.

Energy saving effect after transformation

Record the energy-saving effect of replacing the new high-efficiency plate heat exchanger with the No. 1 furnace of Meishan Iron and Steel 1422 Line. The energy-saving situation is shown in Table 2.

Table 2 Standard coal consumption records per ton of steel before and after transformation

|

|

Stage |

Standard coal consumption per ton of steel(Kgce/t) |

energy saving rate |

| Before transformation (tubular heat exchanger) |

Base period |

51.61 |

|

| After the transformation (Plate heat exchanger) |

2020.2 |

47.18 |

10.64% |

| 2020.3 |

49.84 |

4.22% |

|

| 2020.4 |

48.84 |

6.76% |

|

| 2020.5 |

49.35 |

5.55% |

|

| 2020.6 |

47.41 |

10.26% |

|

| 2020.7 |

47.22 |

10.06% |

It can be seen from the table that after replacing the high-efficiency plate heat exchanger by the tube heat exchanger, the heating furnace rolling line can save 2-4kg of standard coal per ton of steel produced, reduce the gas consumption on the hot rolling line, and greatly reduce carbon emissions.

economic feasibility analysis

According to the use experience of the heating furnace tube air preheater, due to the influence of the surface area of the heat exchanger ash and metal surface carbonization factors, the air preheating effect of the tube heat exchanger in the early 1-3 years of use will rapidly decline, and then tend to be stable. The performance of the new high-efficiency plate heat exchanger is not attenuated within 5 years, and the air preheating temperature is reduced to less than 30°C within 8 years.

Combined with the analysis of the transformation of the heat exchanger of the No. 1 furnace on the 1422 line, the energy-saving and economic benefits of using a new type of high-efficiency plate heat exchanger instead of the tube heat exchanger in the metallurgical furnace are analyzed, and the results are shown in Table 3 below.

Table 3 Economic analysis of high efficiency plate heat exchanger

| Time |

tubular heat exchanger℃ |

high efficiency plate heat exchanger℃ |

Save the amount of gasmillion.Nm3 |

energy saving benefit ten thousand yuan |

| First year |

470 |

530 |

881.0 |

370 |

| Second year |

450 |

530 |

1173.8 |

493 |

| Third year |

430 |

530 |

1466.7 |

616 |

| Fourth year |

410 |

530 |

1761.9 |

740 |

| Fifth year |

400 |

530 |

1907.1 |

801 |

| Sixth year |

400 |

500 |

1435.7 |

603 |

| Seventh year |

400 |

500 |

1435.7 |

603 |

| Eighth year |

400 |

500 |

1435.7 |

603 |

As can be seen from Table 3, after installing high-efficiency plate heat exchanger and tube heat exchanger respectively in the No. 1 heating furnace of 1422 Line, the flue gas waste heat recovery effect of the new high-efficiency plate heat exchanger is better than that of ordinary tube heat exchanger. With the heat exchange efficiency of tube heat exchanger decreasing year by year, the energy saving benefit will increase year by year in the first five years, and the energy saving benefit will be 8.01 million yuan more than that of tube heat exchanger in the fifth year, greatly reduce the cost of gas consumption of steel enterprises

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us