Lean premixed combustion technology

Release time:

2022-03-17

Traditional nitrogen reduction measures only spray water or steam to reduce the flame temperature, but the effect of nitrogen reduction is very limited [1,2]. The combustion science and the formation mechanism of nitrogen oxides have been studied in depth, and the lean premixed combustion is the first modern dry NOx combustion organization technology based on the formation mechanism of nitrogen oxides. The technology was first applied to aero engines, the highest level of combustion organization technology in the industry, and then applied to large ground gas turbines, including ship-powered gas turbines, through the development of aviation-to-combustion.

In the 1970 s, due to the strict control of nitrogen oxide emissions from aviation aircraft required by the official aviation organization of the United States, major aviation engine companies invested a lot of manpower and material resources in the research and development of low-nitrogen combustion technology. Traditional nitrogen reduction measures only spray water or steam to reduce the flame temperature, but the nitrogen reduction effect is very limited.[1,2]. The combustion science and the formation mechanism of nitrogen oxides have been studied in depth, and the lean premixed combustion is the first modern dry NOx combustion organization technology based on the formation mechanism of nitrogen oxides. The technology was first applied to aero engines, the highest level of combustion organization technology in the industry, and then applied to large ground gas turbines, including ship-powered gas turbines, through the development of aviation-to-combustion.

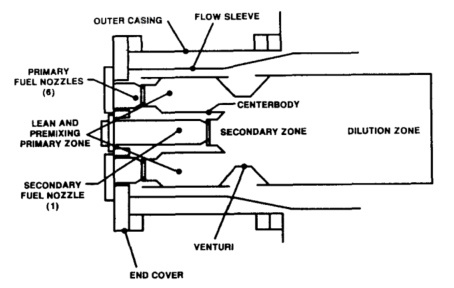

Fig. 1 Lean premixed combustion chamber structure[2]

Fig. 1 Lean and premixing burner schematic

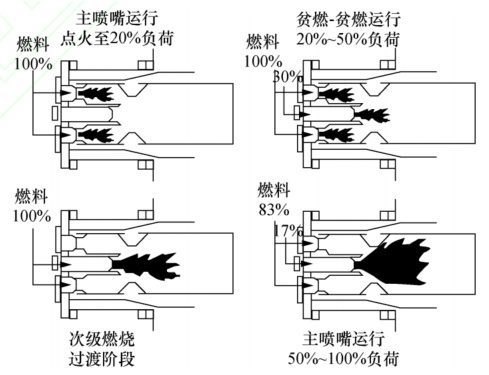

As shown in Figure 1, the combustion organization form of the combustion chamber is through excessive air and fuel premixed combustion, reducing the flame temperature, the primary and secondary combustion areas through the control to avoid the chemical single amount ratio, the highest NOx generation conditions, thereby reducing NOx generation. In addition, due to the staged combustion, the combustion load can be specifically controlled, and different combustion strategies can be configured to meet the load requirements for different operating conditions, as shown in Figure 2.

Fig. 2 Combustion chamber control strategy of GE company[3]

Fig. 2 GE combustor control strategy

The combustion organization technology is the basis of other technologies developed later, and other NOx control combustion organization technologies are more or less applied to this technology, which is a basic control NOx technology. Due to the premixed combustion of most air and fuel, the flame is easily blown out by the air under low load conditions, causing problems such as unstable combustion. Therefore, the technology also needs to be used in conjunction with other technologies, including swirl combustion technology, staged combustion technology, stable flame combustion technology, etc. Other technologies developed later are mostly targeted improvements and extensions.

The combustion technology based on lean premix was first applied in the aviation field, and then extended to the gas turbine field, and obtained good technical results. High-precision combustion organization technology has made great progress in these two fields, but it is rarely used in general industrial fields. Based on this, our company is committed to the domestic general industrial fields, such as metallurgy, petrochemical and building materials industries, the most advanced combustion technology transformation, so that the general industrial fields can also apply the most advanced combustion technology, and then improve the domestic industrial equipment technology level.

References:

[1] Li Suhui, Zhang Gui-hua, Wu Yuxin. Review of advanced combustion technology for future gas turbine [J]. Journal of Tsinghua University (Natural Science Edition),2021,61(12):1423-1437.DOI:10.16511/j.cn ki.qhdxxb. 2022.25.001.

[2] DAVISL B,WASHAM R M.Development of a dry low NOx combustor[C]//ASME1989International Gas Turbine and Aeroengine Congress and Exposition.Toronto, Canada: ASME,1989.

[3] DAVIS L B.Dry low NOx combustion systems for GE heavy G duty gas turbines[C] // ASME1989International Gas Turbine and Aeroengine Congress and Exhibition.Birmingham, USA:ASME,1996

Previous Page

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us