Rychen Attended the Special Technology Docking Meeting on Energy Efficiency Improvement of Converter System of Extreme Energy Efficiency Project in Steel Industry and delivered a speech

Release time:

2024-01-29

The special technology docking meeting on energy efficiency improvement of converter system of extreme energy efficiency project in iron and steel industry was successfully held in Bayuquan District, Yingkou City, Liaoning Province. Chen Wandong, chairman and general manager of Shanghai Rychen, was invited to attend and introduced the comprehensive solution of intelligent steel-making, dust removal and energy saving to the participants, helping iron and steel enterprises to save energy, tap potential and improve efficiency.

On December 21, the special technology docking meeting on energy efficiency improvement of converter system of extreme energy efficiency project in iron and steel industry was successfully held in Bayuquan District, Yingkou City, Liaoning Province. Chen Wandong, chairman and general manager of Shanghai Rychen, was invited to attend and introduced the comprehensive solution of steel-making intelligent dust removal and energy saving to the participants, helping iron and steel enterprises to save energy, tap potential and improve efficiency.

Rychen

Comprehensive Solution for Energy Saving of Intelligent Dust Removal in Steelmaking

Chen Wandong, chairman and general manager of Shanghai Rychen, delivered a technical report on the theme of "Comprehensive Solution for Steelmaking Smart Dust Removal and Energy Saving-Helping Iron and Steel Enterprises to Save Energy, Teach Potential and improve Efficiency". He briefly introduced Rychen's environmental protection achievements and business scope to the participants, focusing on the analysis of the problems and solutions existing in the dust removal system in the iron and steel industry.

Chen always said:

The iron and steel industry is the focus of exploring the road of low-carbon transformation and green development, in which the dust removal device is the key to purify the exhaust gas to reach the ultra-low emission standard. For 10 million-ton steel enterprises, the power consumption of dust removal fans per ton of steel is about 50-80KW. h, accounting for about 15% of the total power consumption per ton of steel. However, the dust removal fan generally has problems such as low efficiency, poor ability, and insufficient automation level. The energy-saving transformation of the dust removal device will have greater energy-saving, environmental protection and cost reduction value.

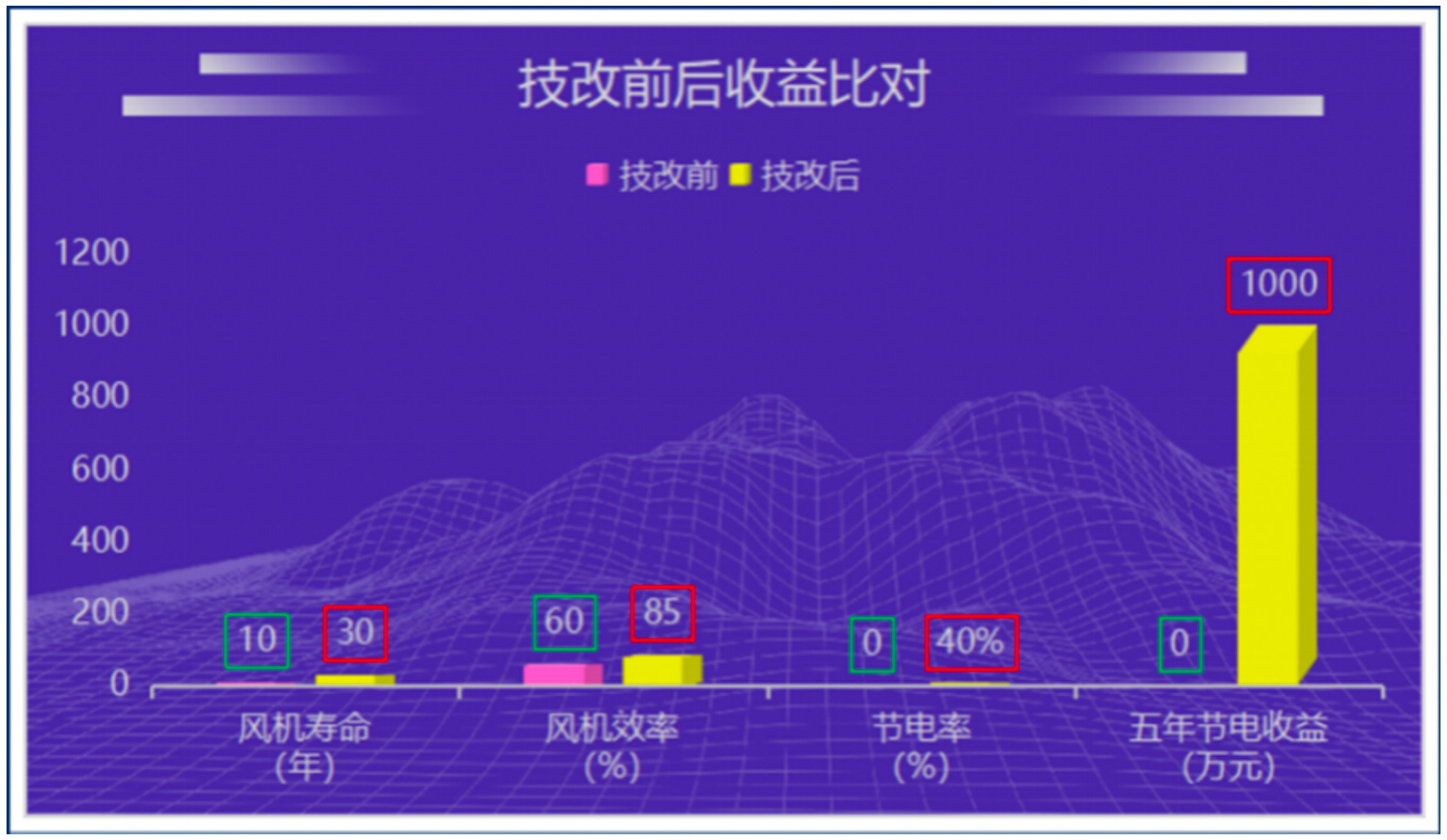

Rychen's intelligent dust removal and energy-saving comprehensive solution for steelmaking focuses on production issues and tailors high-efficiency energy-saving fans according to customer on-site conditions and needs. Through various speed control methods, the average fan speed can generally be reduced by 150r/min. At the same time, the system characteristic curve matching, process control model optimization, pipe network optimization, etc., to ensure the efficient operation of the fan full operating conditions, can reduce the secondary dust removal fan power consumption of 1-2kWh/t, reduce the dust removal system pressure loss of 300-500Pa or so. In addition, Rychen Environmental Protection has also equipped the dust removal device with digital wings. Through the intelligent optimization of the dust removal device, the pressure loss is reduced by about 500Pa. The intelligent acquisition platform completes the work of diagnosing objects, data acquisition, diagnosis and maintenance, and remotely monitors the problem indicators and operating conditions through the intelligent control platform. Handheld inspection, intelligent analysis, real-time monitoring, and intelligent dust removal help enterprises achieve energy-saving benefits of up to 40% or more.

Contact Us

11/F, Building 1, Guozheng Center, 497 Zhengli Road, Yangpu District, Shanghai

Follow us